|

5 October 2014

The latest news is that there's not much to show.

This layout-building process seems to be a mix of frantic activity

and long periods of waiting for the next stage to happen. In those

gaps I'm usually busy on the

Grouping Workbench

modelling work, so it's not actually time being wasted.

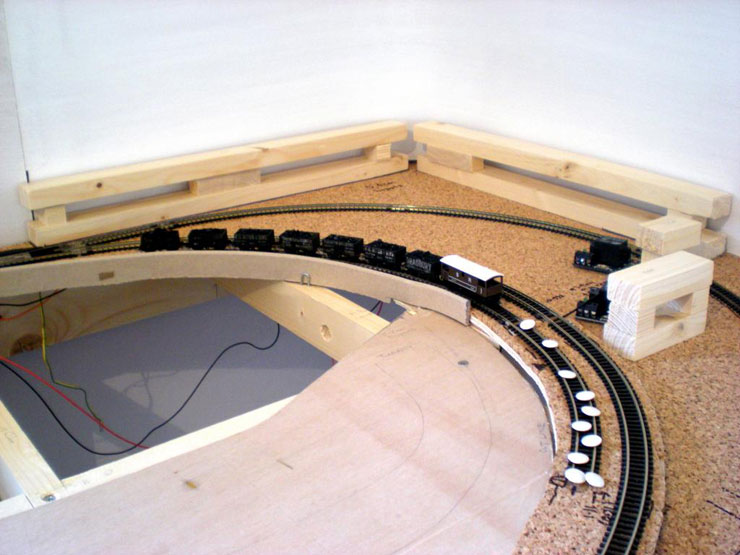

On the plus side, the lower level loop has been

completed (cue 'playing trains' just a little - which is entirely

for testing reasons, naturally). Getting that completed was a major

step forwards, but it wasn't all plain sailing. Working with Peco

flexitrack involves a bit of a learning curve.

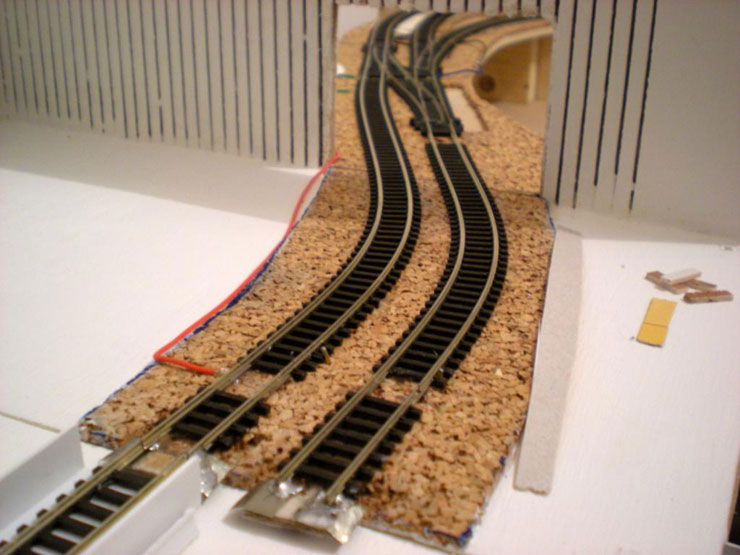

Track laying continues at the front of the layout

(the Evercreech Junction Station area) and at the start of the

incline which begins in what will be a tunnel area, so it's

important to get the transition from flat to incline just right.

The frame for the fiddle yard unit has been topped

with 6mm plywood and is now ready to get some legs:

...and the backing panel has been secured:

This shows the full length of the fiddle yard beyond

the scenic break. It takes up much of this unit, but that's because

the longest train will be a seven coach double-headed express. This

weekend's work also included sawing timber for the traverser tray

and the controller tray, working out which points to link to the

first two relays, and how to wire up the banking loco parking

siding to a 3-way switch.

15 October 2014

Another update:

The shelving at the back of the fiddle yard has

been installed and is awaiting a coat of pain. The tray works

manually but still needs some kind of catch mechanism to be fitted.

I was going to use Bales catches based on Tank's huge fiddle yard,

but I've been strongly advised against that. Hmm...

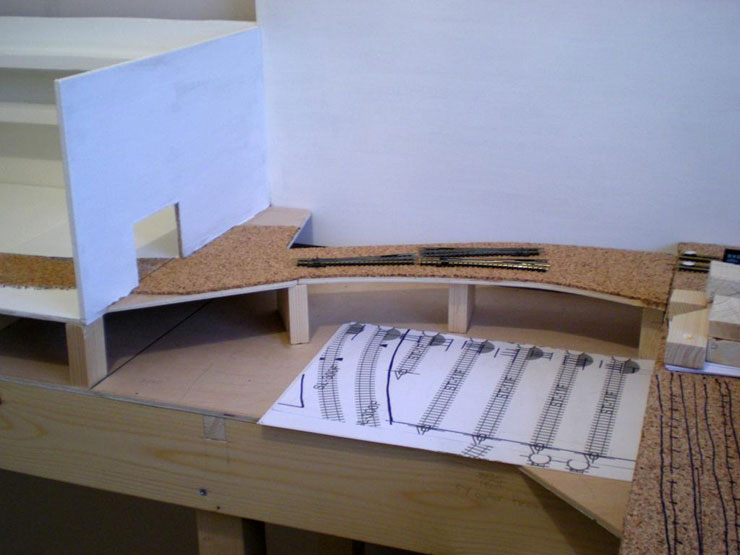

Laying track up the incline and positioning the

first support battens for the upper level:

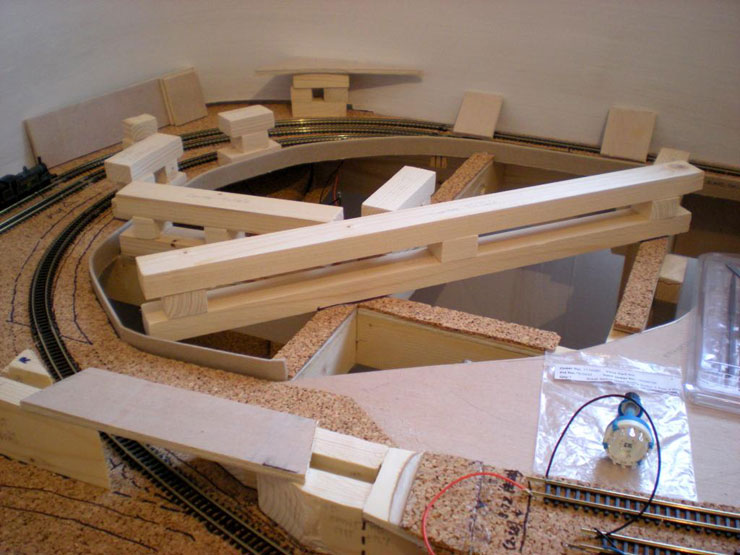

Upper level test:

More support battens in place, but not yet secured:

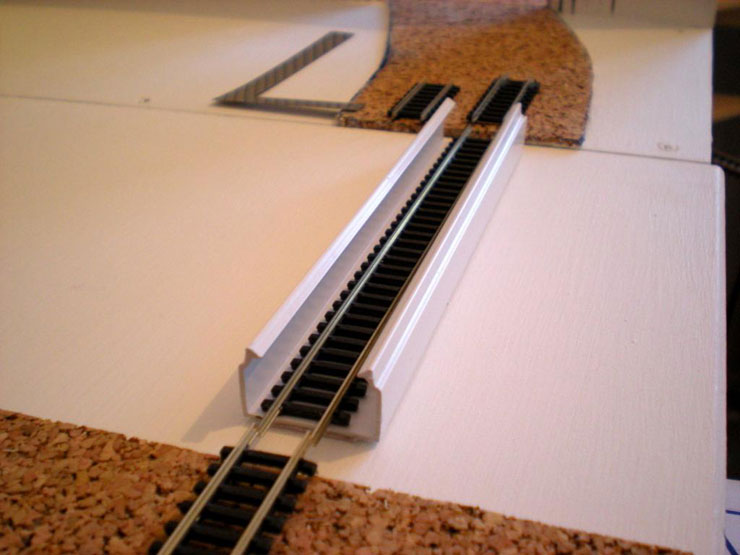

Track base between fiddle yard traverser and main layout in place

but not secured:

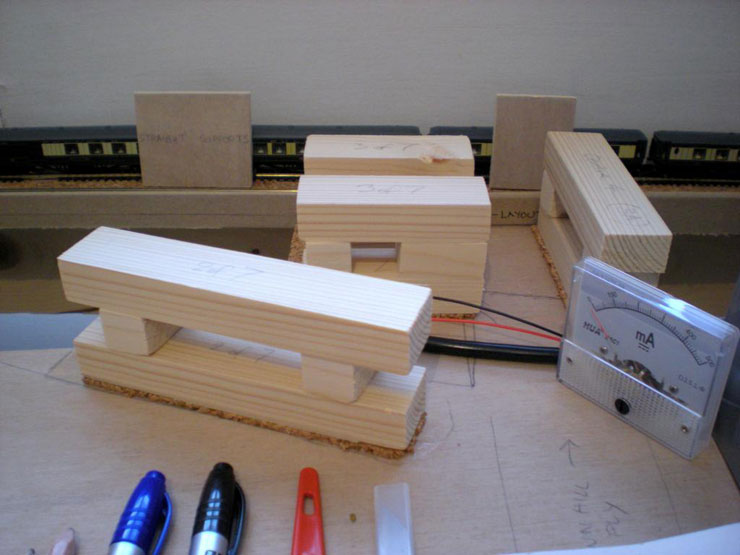

First official wiring completed:

19 October 2014

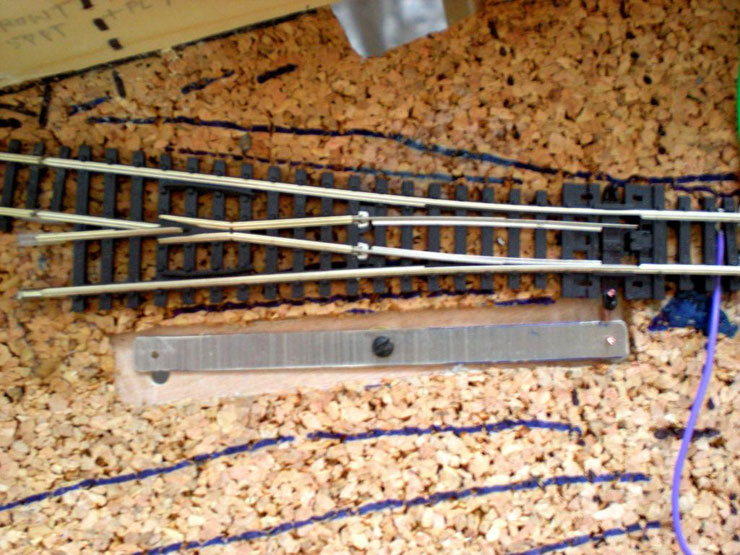

I've had a Jason Statham moment - Crank! Last

minute pre-construction adjustments to the track plan didn't

coincide with last minute adjustments to the baseboard plan, so at

least three points at the front of the layout clash with support

struts. That means some remote points operation is required, and for

that you need a crank: Crank No 1, set up for me by someone who

cares for idiots in the community:

Crank No 2 set up by the idiot in question!

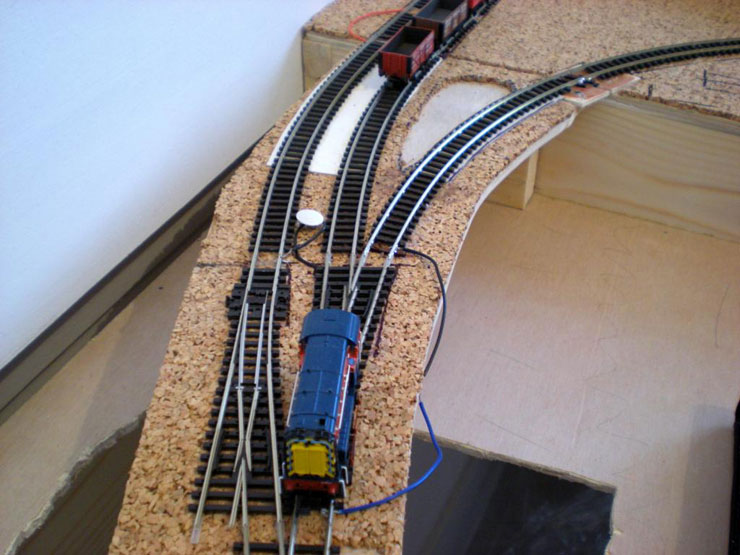

The second platform loop at the front has been cut,

laid, glued and wired (temporarily). It works, but due to the

three-way point at the far end it can't be used regularly for now:

Next stage is to try and complete the upper level

general construction work and start connecting up power feeds on a

more permanent basis...

28 October 2014

Another quick update. The removable upper level is

in place, with two dowels at each end to locate it when slotting it

in, and the goods siding at EJ has been laid (with another crank for

half the double slip):

Now the incline curve has to be completed:

Some support battens under the upper level:

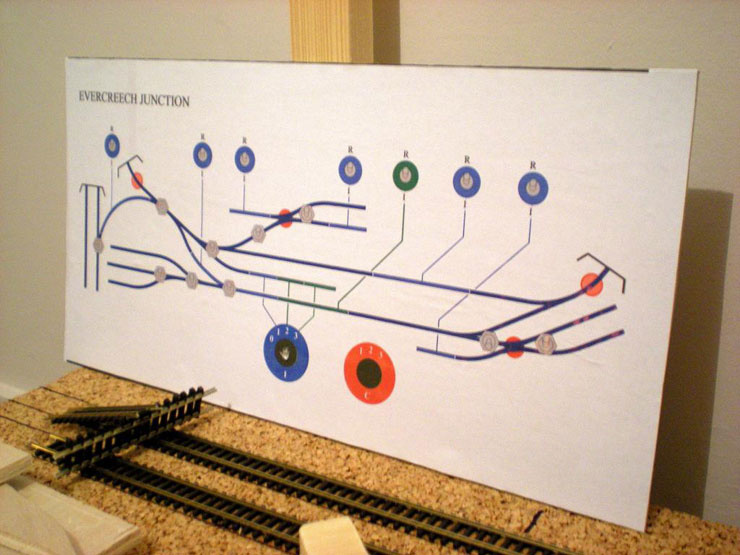

The temporary mimic panel for EJ (Lower Level):

In the meantime, work continues on the fiddle yard

section...

29 October 2014

I should provide a bit of clarification about the

upper level's support battens. The width-wise gaps are there to

allow for points motors. The big gap along the straight edge is due

to the fact that the lower level back straight runs directly

underneath and there isn't space for wooden battens. I'm working on

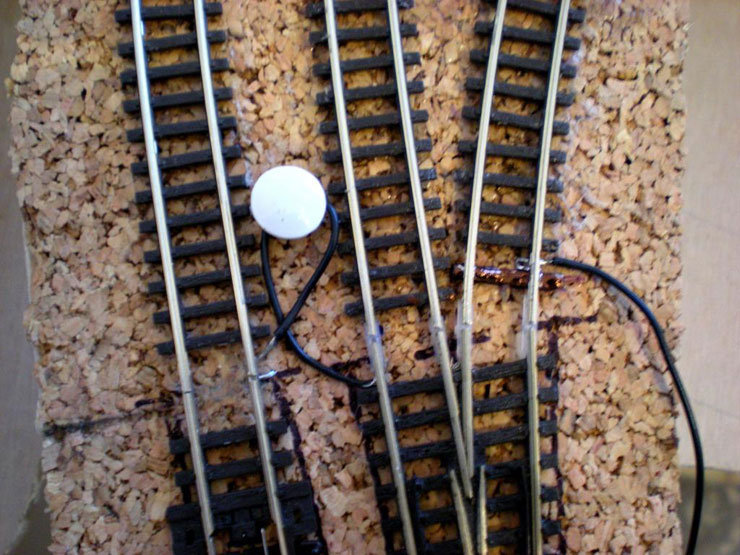

that, and this shot shows the first stage of that solution:

They're 60mm screws which are pretty solidly

anchored, so they don't move around at all. Luckily, the running

lines have a gap between them and nothing comes closer than about

3-4mm to any of the screws, not even the outside-framed Class 08.

Stay tuned...

6 November 2014

While I wait to get my hands on the extra supports

for the upper level, construction work has switched to the

detachable fiddle yard. The baseboard and frame were put together

some time ago (see photos, above), but the legs still needed to be

done, complete with wheels and adjustable legs:

Admittedly, the adjustable legs should have been

fitted to the outside or inside of the legs, rather than behind

them. They tend to foul one set of wheels in the direction of

travel. Testing the positioning of the fiddle yard unit:

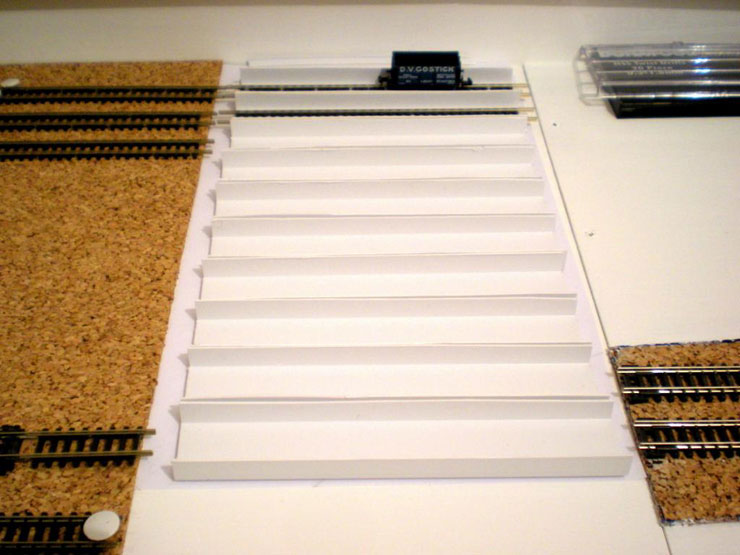

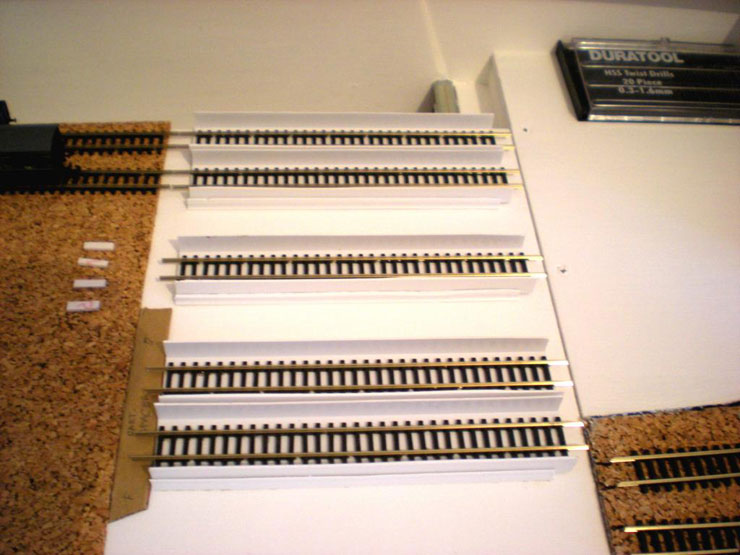

Testing how many storage lines I can reasonably

squeeze in (the answer is ten and three quarters):

Clamping the fiddle yard unit to the main board in

preparation for drilling two bolt holes and four holes for locating

dowels (above the block with all the markings on it - that's a

left-over from an entirely different bit of work):

10 November 2014

Here's the latest update, although most of the work

recently has been preparation and not much progress. Testing the

traverser for train length. It can easily take seven coaches and a

double-header:

The piece of brown card is a tester for a cartridge

system. The plan is to have a cartridge at each end of each storage

line. Incoming trains run up to the end so that the loco is on the

cartridge, and then this can be lifted, turned, and placed at the

other end of the traverser, with an empty cartridge replacing it.

Any ideas for building the cartridges? I have 3mm ply to start

with...

The upper level was set to the correct height, but

when testing the last part of the incline (from the bridge to the

upper level joint), the climb seem to steepen for the final 20cm or

so. So the upper level has to come down a bit. Luckily, the support

battens are on a layer of 3mm cork, so this is coming out. Saving

3mm might be enough to make all the difference. It means ripping out

each support batten, scraping off the cork, and re-gluing the batten

in place. It can't be done all at once to avoid the dowels being in

the wrong place - much easier to do each half separately, and the

first half is now done:

One smelly undercoat on all the visible surfaces of

the fiddle yard. The next step, once it dries and the fumes clear,

will be to lightly sand it and then add two coats of leftover

ceiling paint:

20 November 2014

Just about got time for an update (work has been

manic for the past couple of weeks). The fiddle yard has received an

undercoat and four topcoats, and seems to be looking good:

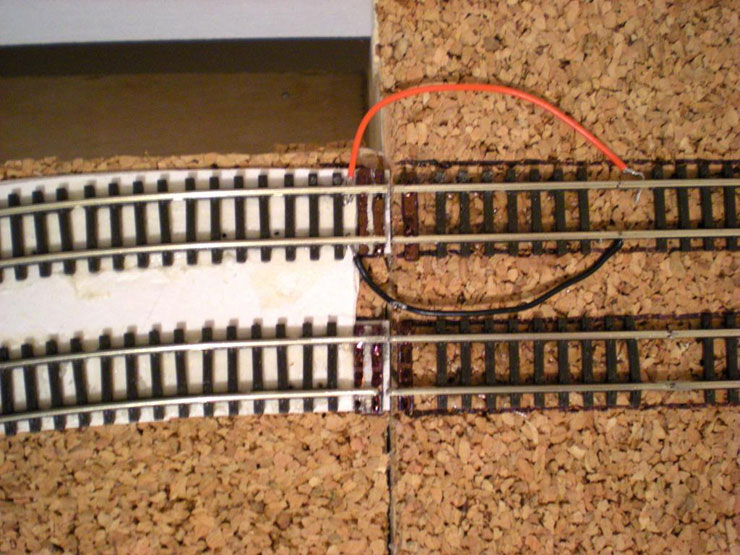

Now to bridge my first baseboard divide and get the

track extended onto the embankment:

Two glues to stick down the brass bits and one

soldering iron to secure the track to them... messily. I used

Minitrix rail joiners laid upside down on top of the rail head to

make sure the bridged section remained in line (Minitrix joiners are

bigger and wider than Peco Code 55 types), and then glued down and

pinned the curved track, wrestling it into place in about ten

minutes of work. Luckily the glue dries fairly slowly:

First over the gap - the engineering train headed

by the 8F and its long wheelbase:

Second track down and the brass bits masked with a

black marker pen. Once the ballast is down this should look okay:

The view from the fiddle yard:

Stay tuned for more...

10 December 2014

Not much done recently due to weight of work and

also a large number of new pages to prepare for publication on the

History

Files in just over a week, but here's the little progress that

has been made. Cork laid across the traverser tray, allowing spaces

for loco cartridges. The three lines at the back will be for full

length trains, so a central cartridge won't be needed.

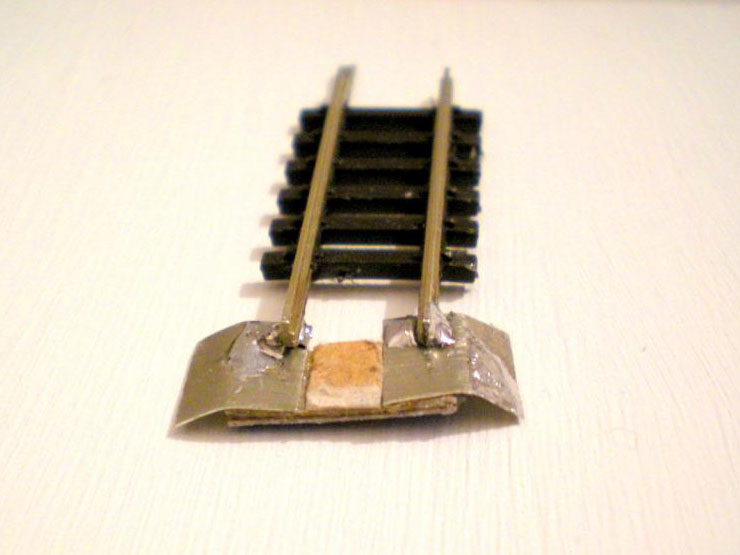

Here's the early prototype loco cartridge, simple

26mm cable trunking with self adhesive base. It needs to be raised

(so the self adhesive will come in useful):

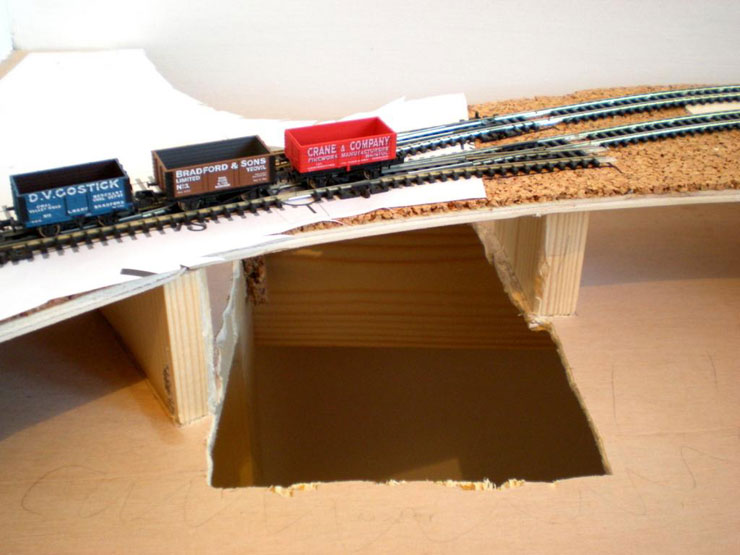

And it suddenly dawned on me that there was no

access point for positioning points motors under the embankment.

Whoops. One hack and chop later. Mind the gap, lads...

17 December 2014

With the preparations under way for Christmas and

things at work winding up, I've had spots of time this week to do

little bits of work on the layout here and there. The Highbridge

Loop (aka short cut to the fiddle yard) has been laid and is open to

construction traffic only:

The other end of the loop crosses a baseboard joint

(cue the overuse of much solder to ensure the tracks don't ping in

opposite directions when they're cut next year), and joins a

junction at a fairly tight radius. It's never going to be used by

anything with a long wheelbase so that's fine. But it meant that

getting the end of the curve to align with a point fitted with IRJs

was a bit of a nightmare. Luckily, using Copydex the first time

allowed me a second bite of the cherry and the chance to get rough

with it. This time it's aligned and it'll stay that way:

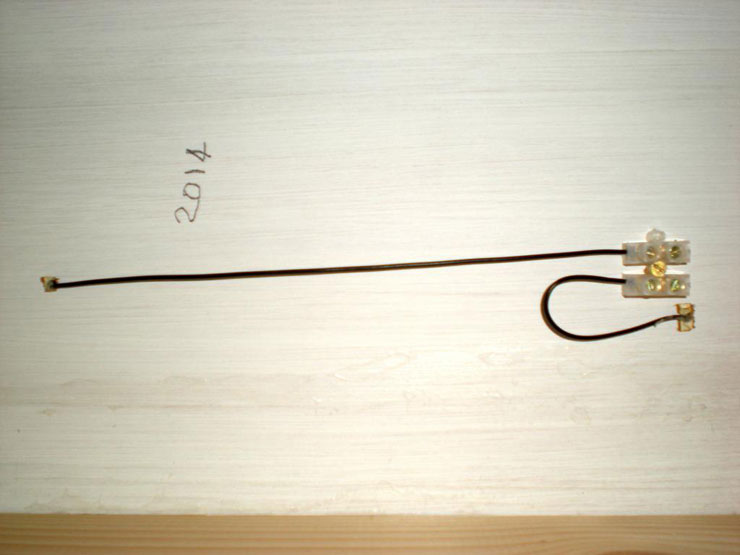

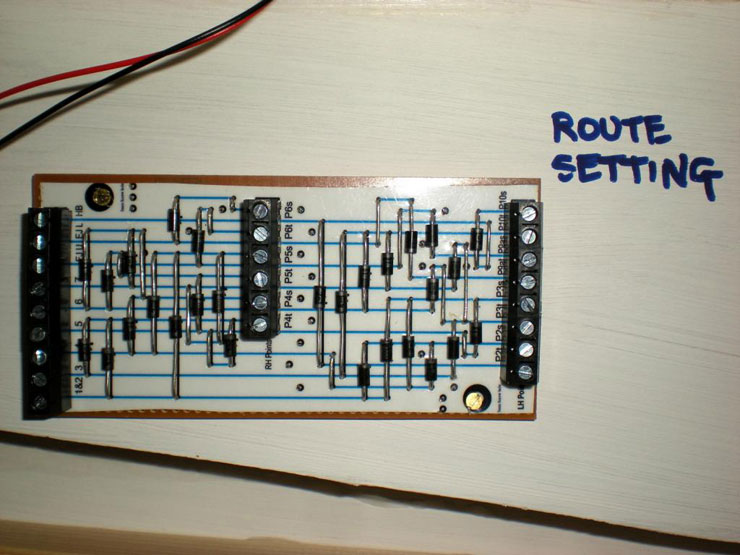

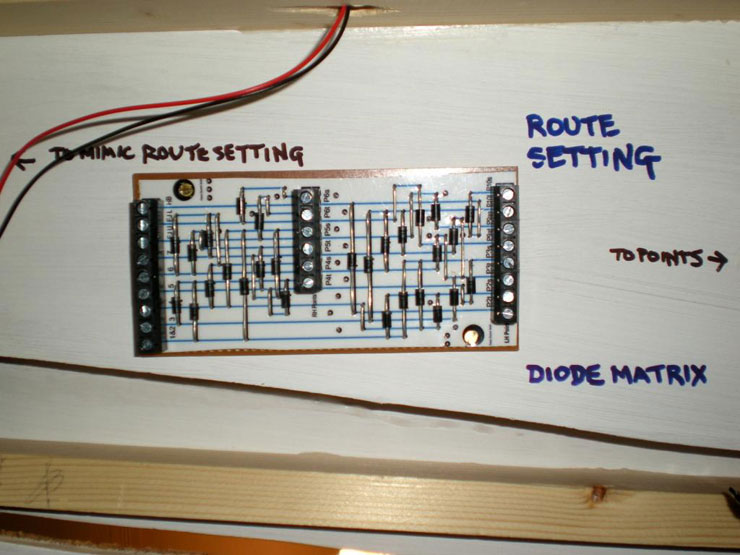

The diode matrix for route setting - fitted at

last!

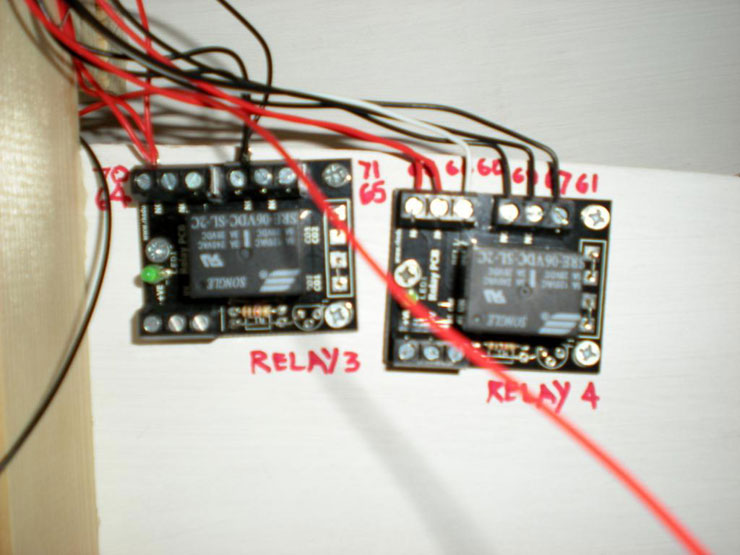

Relays fitted and wired in, although they aren't

operational yet:

More loco cartridge tests on the traverser. Results

encouraging:

First points motor fitted but not operational. How

on earth are you supposed to test whether they've been properly

fitted...?

That's pretty much it. The Highbridge Loop is still

drying off so I won't be able to test that today. The loco

cartridges need a couple more cartridges to be fitted with track so

that I can test for misalignments. It looks unlikely that the first

loco will be able to make its way to the fiddle yard this year.

22 December 2014

I had a bit of a brainstorm in regard to the

traverser wiring and power connectivity and spent a furious half

hour scribbling down notes that will cover just about all of the

rest of the work. So the way ahead is clear. I just have to find the

time to do it.

As for the points motor, I suppose I used something

similar, only less hardening - blu-tack! A small blob on each corner

of the mounting plate allows you to hold it quite easily in position

while you mark out the screw holes for pre-drilling and then secure

the motor itself. At the moment I still haven't been able to test

the motor so that I can be sure it's correctly mounted.

23 December 2014

Just time before Christmas for an update of the

weekend's work. Firstly, an overview of the tricky junction. It

crosses a board joint and meets a junction (nearest the camera) at a

pretty tight angle (somewhere midway between R1 and R2, I think):

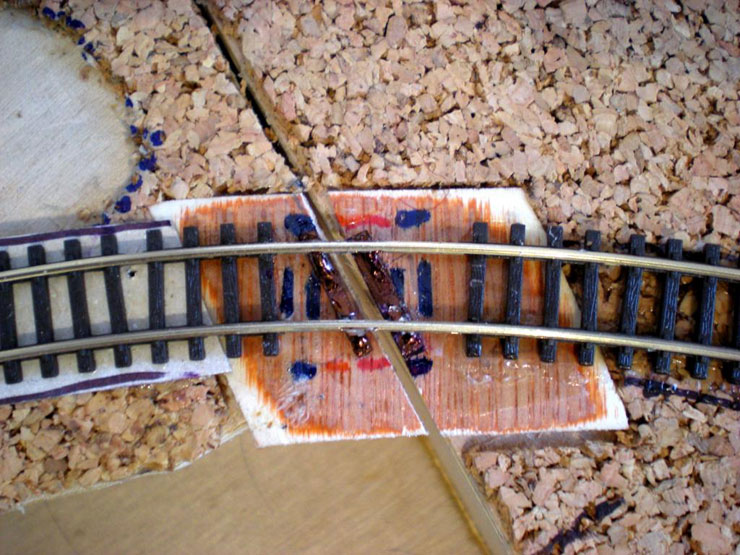

Where the track crosses the boards, it has been

soldered to PCB strips that are superglued to ply inserts in the

cork. The hope is that when I can get me a razor saw and cut the

rails, they won't go 'ping' and rearrange themselves into an

entirely new track configuration:

At the junction end it needed another strip of PCB,

temporary metal rail joiners until everything had set, and a

bucket-load of solder to cement it all in place:

And now attention turns to the soon-to-be-connected

fiddle yard. The loco cartridges are mostly ready for testing,

although they still need some work to complete them. The spacers are

being put in place to divide the cartridges, and these come from

off-cuts from the £1.56, two metre-long cabling duct, while the

cartridges use another part of it to raise them the required amount.

Nothing (much) gets wasted:

Progress on the fiddle yard in January should be

good...

19 January 2015

A quiet week after Christmas meant that I was able

to push on with electrics and fiddle yard work. My unpatented fiddle

yard-to-traverser connecting rail with power transmission. Otherwise

known as a scruffy piece of brass and card with some dodgy soldering

to secure it. It works pretty well, but I'm betting that a much

tidier version can be made, just not by me:

Here it is in place. The curved sides allows each

of the traverser storage lines to ride over it as the traverser is

pulled out:

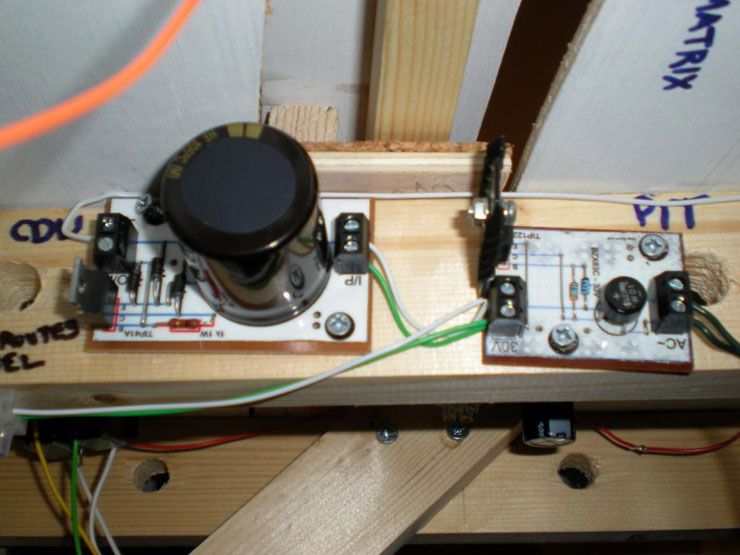

And meanwhile, underneath the main board, the PIT

(a power board and plugged-in power supply) and CDU have been

installed:

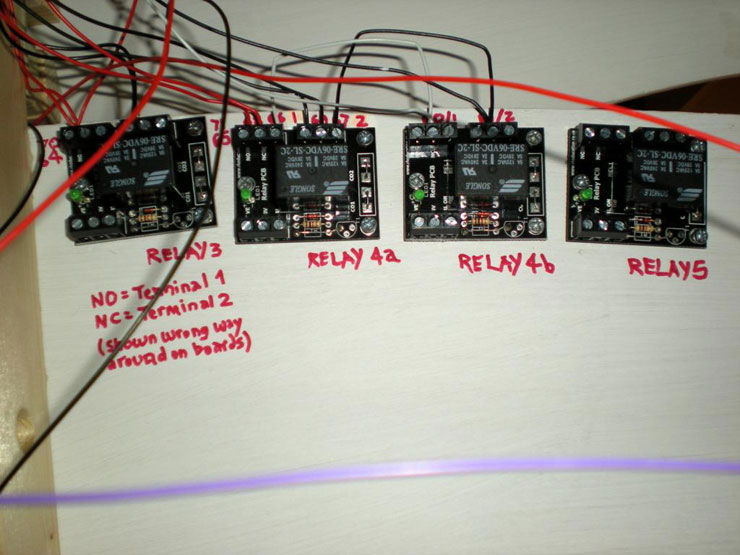

Two more relays attached (Relay 4b is solely to

allow the fiddle yard to be taken over by Controller 3 while 1 &2

still power the main line). Writing upside down with a felt pen is

fairly tricky:

The route setting board:

And finally for now, the main line reaches the

fiddle yard!

|