|

1 September 2014

And so it begins...

This thread continues from the Layout Planning

section which can be accessed via the 'Layout Work' link at the top

of the page.

After a year and-a-half of plotting, planning, and

fine-tuning, construction work on the layout finally began a couple

of Saturdays ago. It took this long to get the main baseboard up

(literally) and running (on wheels, no less), with pesky work

getting in the way, but this is what I have so far.

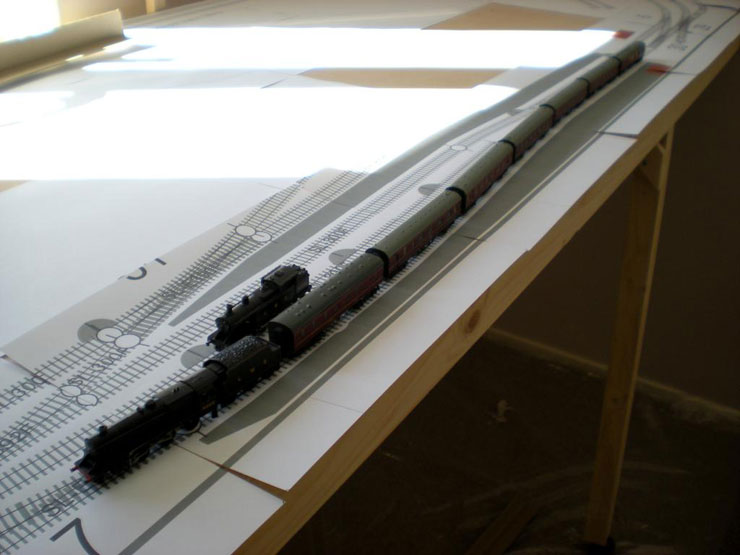

The first photo shows the main board, which is

2540mm x 800mm (that's around 8ft 4" x 2ft 7" for you

old blokes who can't cope with the modern world!). The framing

is solid enough to ensure no warping, hopefully, and the removable

backscene boards are propped in place by the vertical posts.

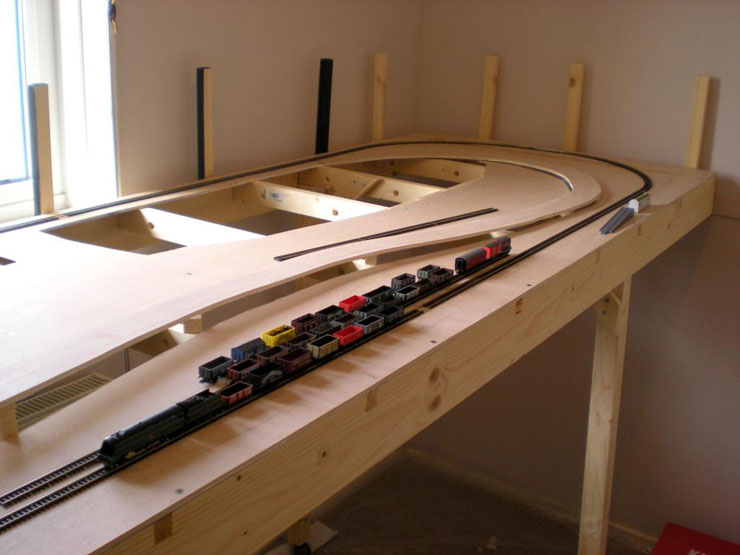

The second photo shows the layout with the main

board in place.

I also managed to translate the track plan from

paper onto the baseboard, and couldn't help playing trains with a

display shot of a full length 'Pines Express' at Evercreech (albeit

in late 1930s mode). That's in the third photo.

The next step is to mark the cut-outs for the

incline and the access points towards the back of the baseboard,

where the upper level will be sited. A quiet afternoon and a bit

of dry weather will be needed for that.

7 September 2014

Not too much to report since last time. During

the week I was able to find the odd hour or so to be able to do the

cutting-out. The large open areas will be where the upper level will

sit, so I'll need to be able to access the underside of this for

installations and repairs. The upper level will be removable for

major work, but removing it could be a little complicated, so I

don't think I'll be doing it every day.

Also cut out was the first - and biggest - part of

the incline to the upper level.

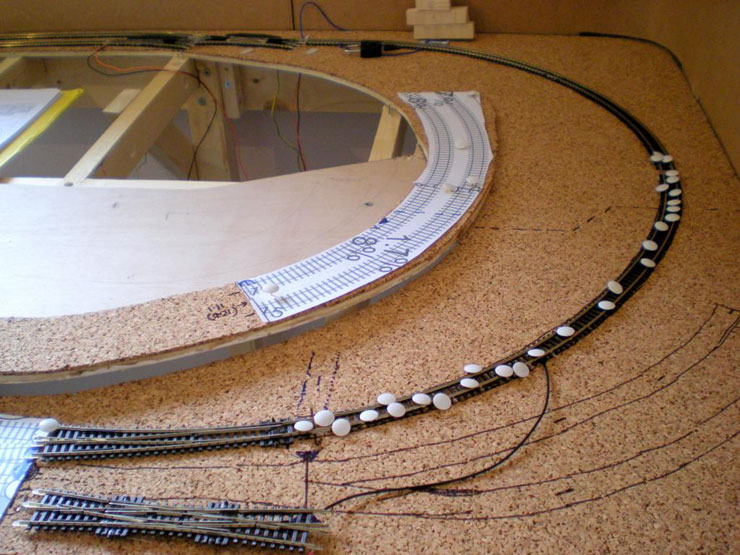

The oval of track was a temporary test loop for

warming up locos and cleaning wheels for the Yeovil NGF meet

yesterday. It has gone now (for the time being, at least!).

9 September 2014

A bit more progress... Cork has been laid (under

just about all railway-related books, several planks, three 5L tins

of unused paint, and the timber for the fiddle yard traverser to

weigh it down), and the first shot shows the semi-fitted first part

of the backscene, which simply slots into place.

The cut-out areas of baseboard have been cut out of

the cork, as has the scenic area in the middle. Actually, there's a

lot more scenic area than expected. Hopefully the upper level will

eat up some of it. The rest will be formed of the yard next to

Branskome MPD and the street that ran alongside Bournemouth West

Station.

Today, from Poundland, I bought some cheap

double-sided sticky tape (the expensive stuff is just too sticky)

for sticking down the track prior to ballasting, and some

fine-tipped marker pens for marking out where the track will go.

Almost there with some permanent, live track...

12 September 2014

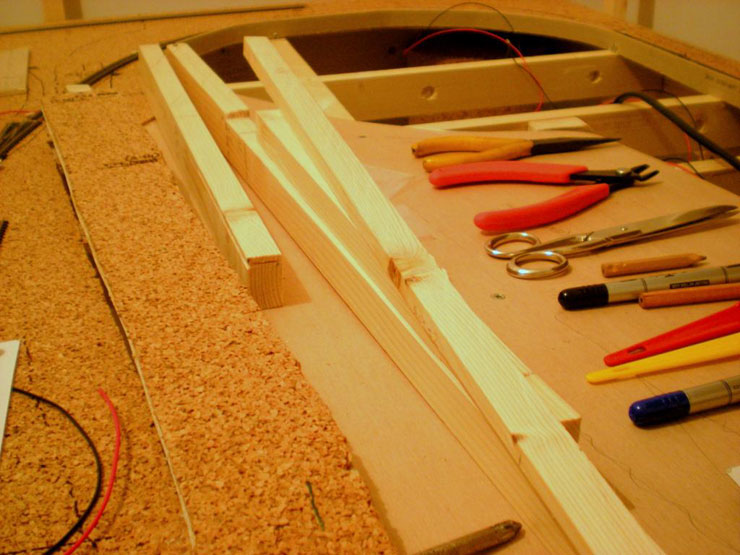

Slowly (oh so slowly) getting there... A simple

retaining tool for a removable protective barrier:

Providing that protective barrier for the hidden

back straight to avoid locos and trains plunging to a fiery death in

the gaping chasm below:

The finished backscene. Don't worry about the

corner gaps as they'll be hidden by the upper level. To be honest,

Flexi-MDF is a nightmare to work with. You'd be better off going for

something much thinner, lighter, less flexi, and just add your

curved corners with a flat piece of (diagonal) board or a thick card

insert:

The gap at the far end is for the final piece of

backscene which will fill the span between there and the start of

the fiddle yard (still to be built):

Now onto trying to secure the first pieces of track

(a minefield for the nervous beginner in itself!). I have Copydex

and I also have double-sided sticky tape. The latter has been

advised because it makes it easy to reposition the track, but I've

also been warned against it because it will degrade and jeopardise

future track stability. I've also been advised about hot glue (a

tube of Bostick left in the sun for too long?), but I'm guessing

that my best option is probably the Copydex.

Also, where exactly would you drill a hole next to

a set of points for a Seep point rod. Does anyone have any diagrams

or photos for an idiot? How do you mark out where the hole goes for

the power feed for Electrofrog points (the extra silver wires that

are attached to slips and 3-ways) while the point itself is sitting

over the potential hole? All these questions and more will never be

answered unless you dive in and sound off.

12 September 2014

This, adapted from a post on a forum, also sees to

cover points motor installation in pretty good detail:

-

Lay the track. Decide which side you want the

point motor connected to

-

Use a sharp pencil or pen, place it through

the tie bar hole to draw where the arm will go. Do this for each of

the tie bar's positions

-

Remove the point, and join up the two little

lines

-

Use a 1.5mm or 2mm drill bit and drill out

the entire length of the line. This leaves a slot under the tie bar

-

Clean up the hole and offer up the point to

it in order to make sure that it lines up

-

Glue down the point (Copydex in my case)

-

On the underside of the board, draw a long

line extending out of the ends of the slot, along the middle,

indicating the slot angle

-

Once the glue has set, offer up the point

motor, and mark off the length of the arm, and then cut it down

-

Take three bits of cardboard (about 1.5mm

thick) and wedge two of these on the outside of the point blades,

in order to centre them. The third piece is cut to the gap in between

the electromagnets on the motor. A slot is cut in the middle to again

centre the point motor

-

Insert the motor, and align the central rod

with the line drawn earlier

-

Screw it into place. Remove the bits of card,

and most of your motors should be pretty well centralised

That seems to cover most of it, plus making sure you

widen the tie-bar hole and mount the Seep on small blocks under the

baseboard. I do think the cork underlay was a good idea. It does seem

to do quite a bit of sound-deadening so far, and of course it gives you

a bit of lee-way with errors in drilling.

20 September 2014

Things were going pretty slowly until Thursday's

pinning down and bug-fixing day. If I had known just how difficult

Code 55 flexitrack was going to be with anything other than straight

sections then I might have been tempted to stick with Code 80. Never

mind, it's getting there, and Code 55 does look better.

To start with, pinning down a tricky curve prior to

dripping diluted PVA between the sleepers to hold it down (there was

no way I was going to lift this to apply Copydex):

Complex height measurements for the incline

supports and bridge:

The engineer's train, for testing purposes. A

long-wheelbase loco like an 8F is ideal for testing curves. If that

doesn't get stuck on a curve that's too tight, pretty much nothing

else will:

Support pads to go onto the exposed battens under

the incline so that the space can be brought up to surface level:

Another, even more tricky curve. This one proved to

be such an unhelpful so-and-so that the junction has been nicknamed

Unfriendly Junction:

One of eight support pads glued into place:

The view from the depths:

The incline support - essentially one single strip

of wood for the most part, cut with a finely-measured slope to it,

and then cut again into three or four pieces so that each piece will

sit on a support pad and the next piece can start alongside it (this

is so that it can cope with a snake-like curvy incline). The next

job is to test these in position before gluing:

The incline has already been tested in rough terms.

All sorts of tank engines made it up there with enthusiasm to spare

and hauling three Farish suburban coaches - all except the infamous

Dapol M7. That's going to need some extra weight added, although

perhaps the incline will be a little more gentle once I have the

proper supports in place.

20 September 2014

The continuous loop is close to being finished, but

the curve coming out of Unfriendly Junction may need to be relaid

first. Then there's just the station straight to connect and some

jury-rigged electrical feeds to put in place to bypass the isolated

sections, and the playing

testing can begin.

27 September 2014

Progress report.

The incline support 'post' has been cut to shape

and put in place, and a more serious test of locos was held. With

three suburbans, the BachFar Jinty made it up okay but visibly eased

off (realistically, of course). The Dapol Terrier motored up quite

nicely at low speed. Best of all, the Dapol M7 cruised up, with a

little bit of a slow-down where it crossed from the curve onto the

straight (two different pieces of track). Still realistic, as far as

I can see as the real thing was unlikely to hit a 1-in-63 slope

without some slowing down. The point is that it didn't struggle and

didn't sit on the spot, wheel-spinning. The incline works!

First part of incline support glued in place and

weighted, and with a spirit level across it to ensure that it's

entirely level. Plus the fiddle yard section has had its frame cut

out, glued and screwed (it's upside down in this photo):

I've also started to complete the running loop with

the last few sections of track on the northern side of EJ. Hopefully

can complete that tomorrow.

28 September 2014

Today's work was all structural:

The ply for the fiddle yard base was cut out, given

a coat of white ceiling paint on the underside, and glued and nailed

into position (I've run out of small screws).

The ply for the upper level on the main board was

cut out, and given a coat of white paint (and is now littering my

hallway while it dries).

The rest of the backscene panels were given an

undercoat (yep, you've guessed it - white).

The backing panel for the fiddle yard was cut out,

along with three shelving strips for extra rolling stock, and two

more pieces of support 'post' for the incline were glued into place.

Nothing much worth photographing, though, but it

will help the general layout look better eventually.

|