|

28 April 2015

Time for another update.

Work on the first carriage conversion has been

ongoing, but there are stages in which not very much at all seems

to happen, and then you reach a stage where very much indeed seems

to happen and suddenly you're a whole lot closer to completing the

project. Building the layout has been a very similar process so

far (see the

Layout

Work thread).

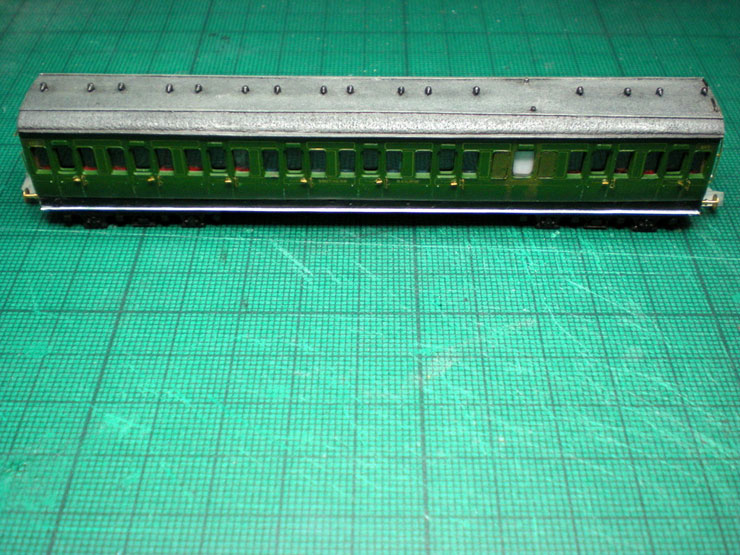

The holes for door handles and grab handles have

all been drilled, using an 0.5 bit. That's not as easy as it sounds

as I broke a drill bit by pressing too hard. You have to allow the

drill bit to find its own way through the plastic.

You also have to be careful to place the grab handle

drill holes immediately above and below the existing moulded grab,

and I seem to have drifted a little in some cases, which is all

too easily done. Never mind, they'll fit eventually, after a bit of

pushing and tweaking, and no one will be any the wiser:

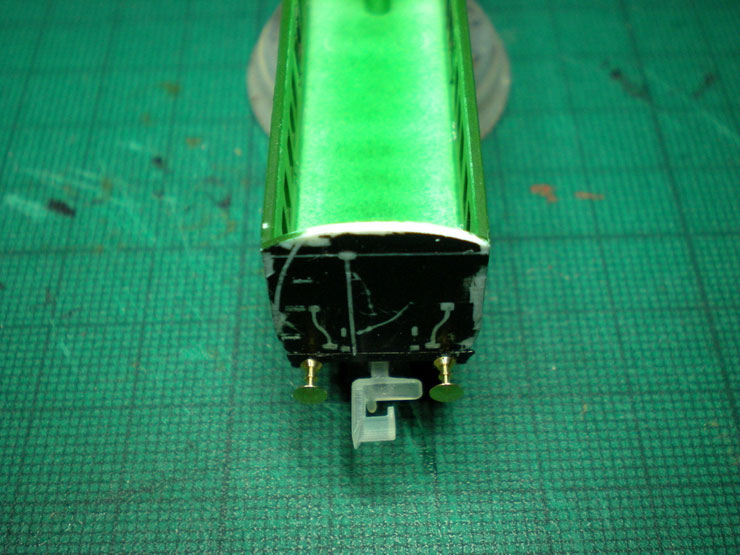

Before adding the new handles, it's best to carry

on with the demolition work first, so I scraped and filed off all

end-carriage detail, and also peeled off some of the top edge - a

little too much as it seems that the existing ends will do fine with

the new roof, with a minimum of filling around the gaps. So be very

careful to peel off only a little of the central top edge of each

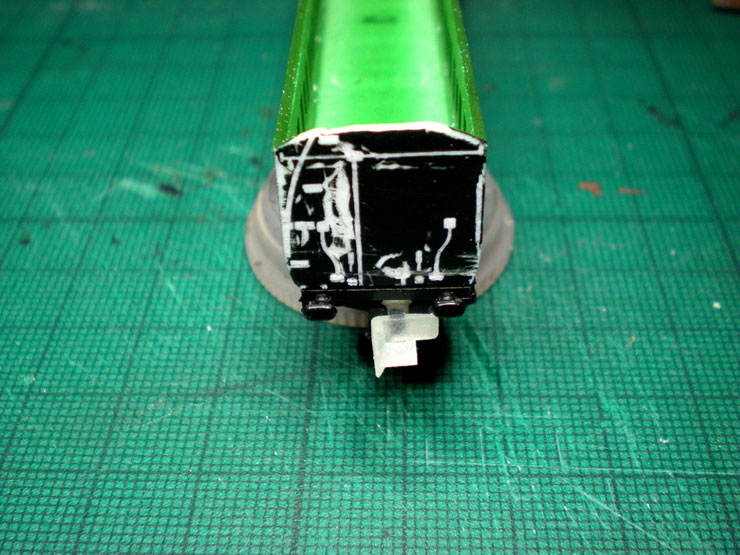

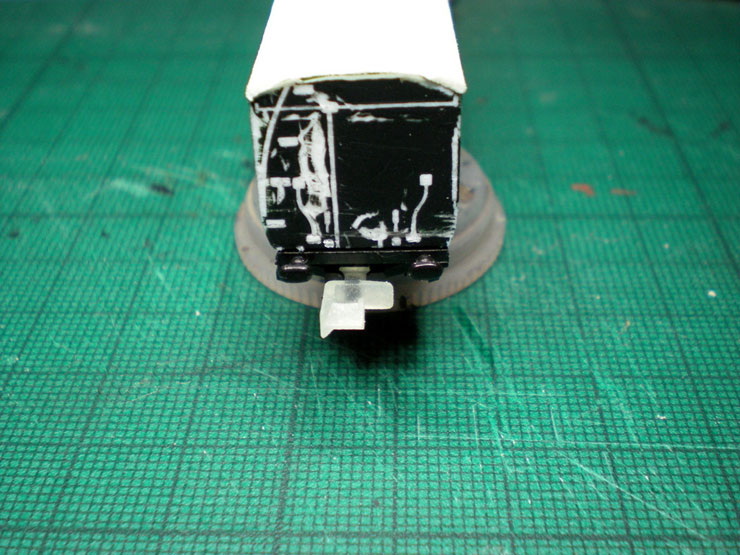

carriage end:

The Etched Pixels 3D-print roof needs to have its

supports pruned back so that it sits over the carriage end. Only a

millimetre or so needs to come off, and again, I know this because I

took off a little too much:

When fitted, the new roof will sit over the end

pieces quite nicely:

5 May 2015

The tricky part about experimental work like this

is that you're not entirely sure of the order of work until you get

there. I've rearranged the list several times and am still making

minor changes. It'll all be much easier next time, but progress this

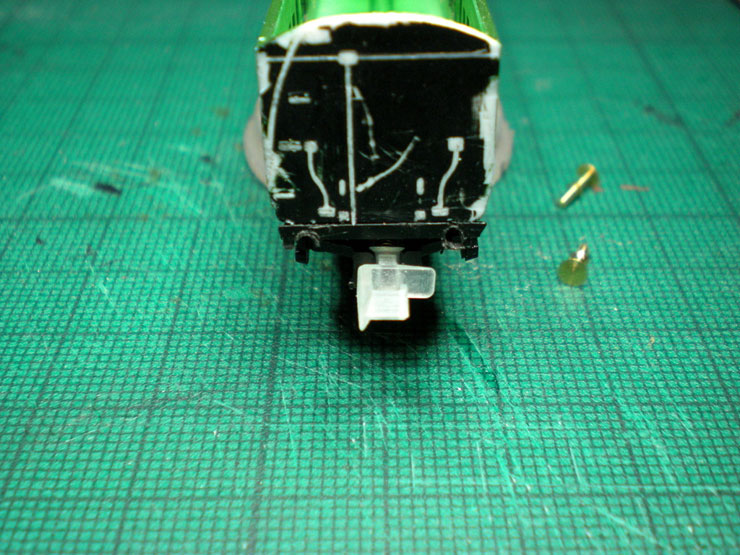

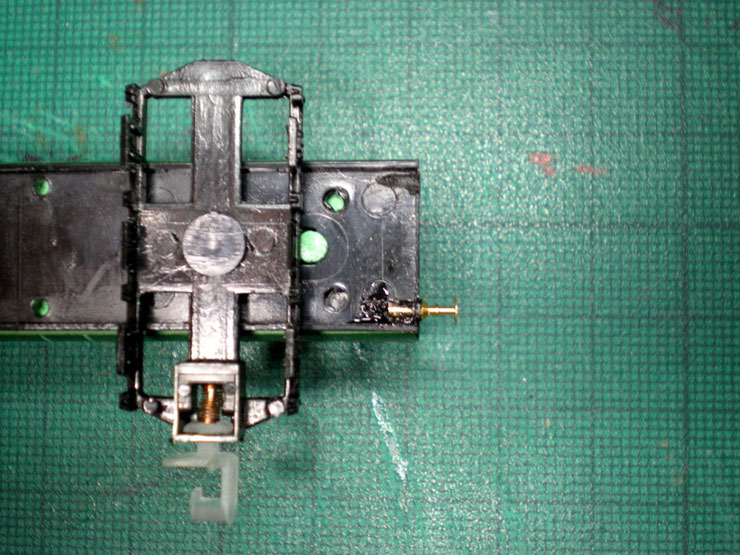

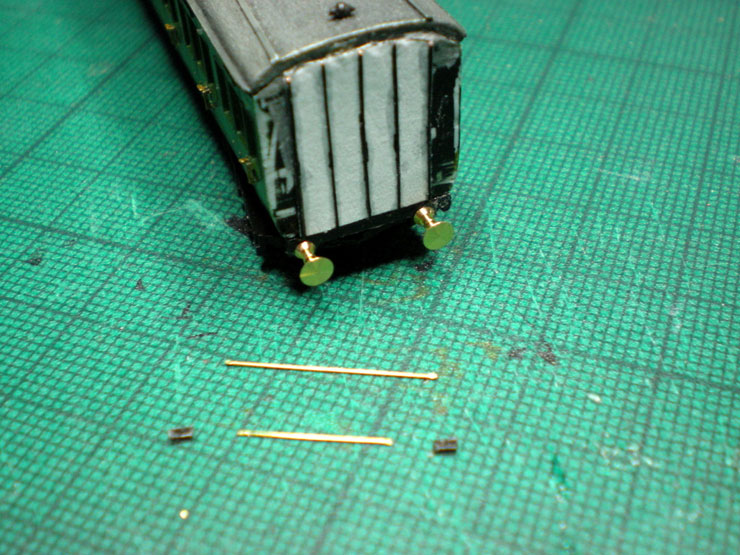

time is slow - albeit very encouraging. More destruction before

construction - cut off the old buffers and file smooth, mark a

centre point using something like a set of old pizza cutter wheels,

drill a pilot hole, and then a larger hole for the Etched Pixels

brass buffers:

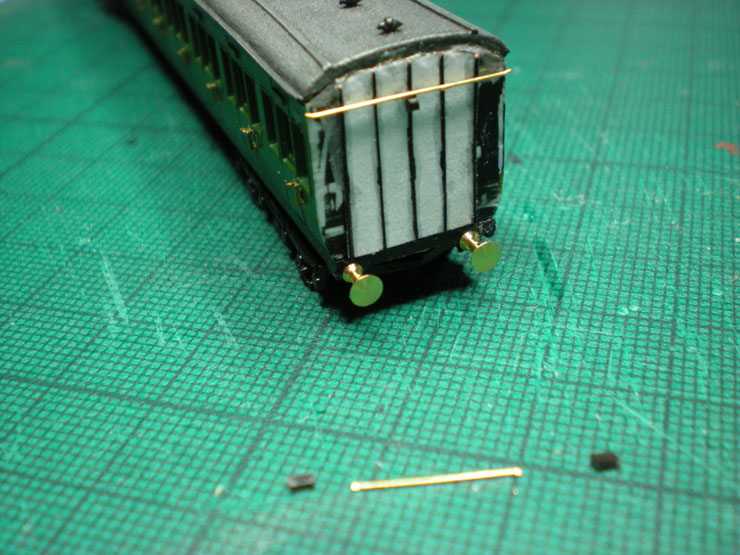

The hardest part is making sure both drill holes

are entirely level:

Managed it at one end (shown below), but the other

end was a bit wonky. Luckily a quick bit of padding inside the hole

forced the wonky offender downwards into leveldom:

A mix of Bostik and superglue liberally coating the

holes and covering the fitted buffers offers flexibility and

strength... usually. All four buffers in place. They're noticeably

longer than the old ones so my hope of close-coupling goes up in

flames. Next time I want to find LSWR-pattern buffers with a shorter

shank:

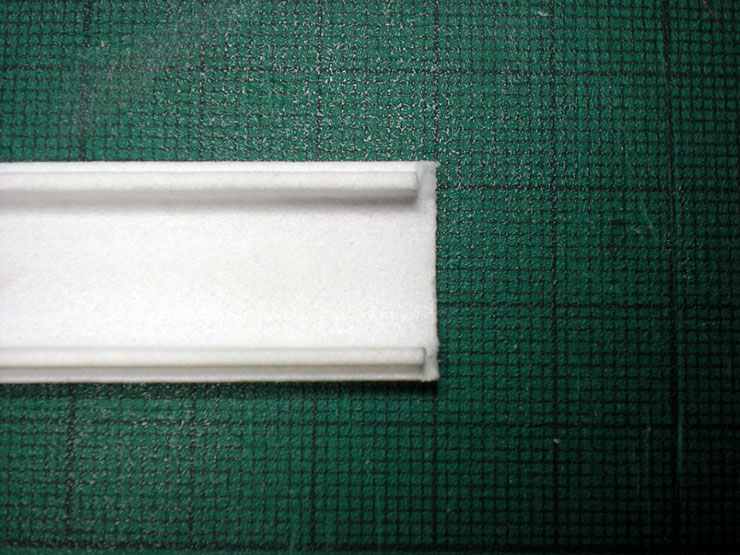

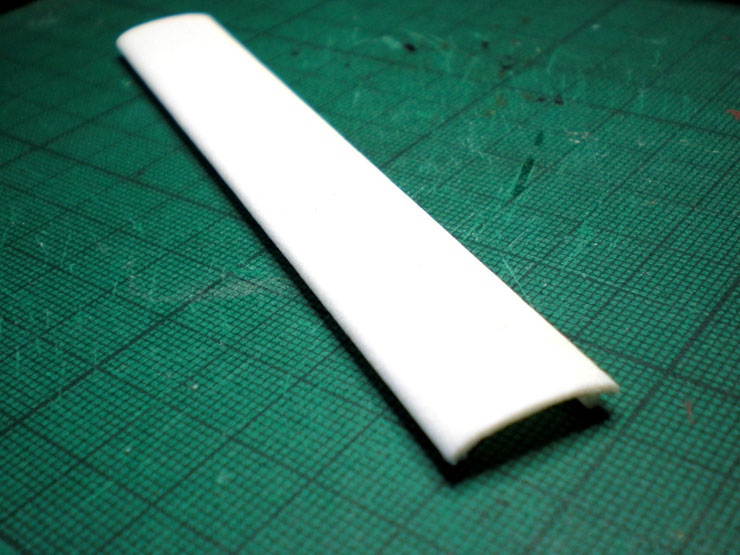

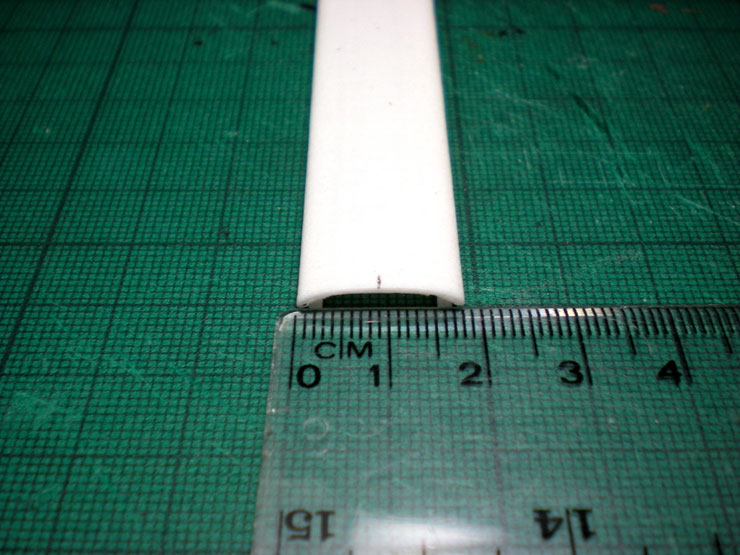

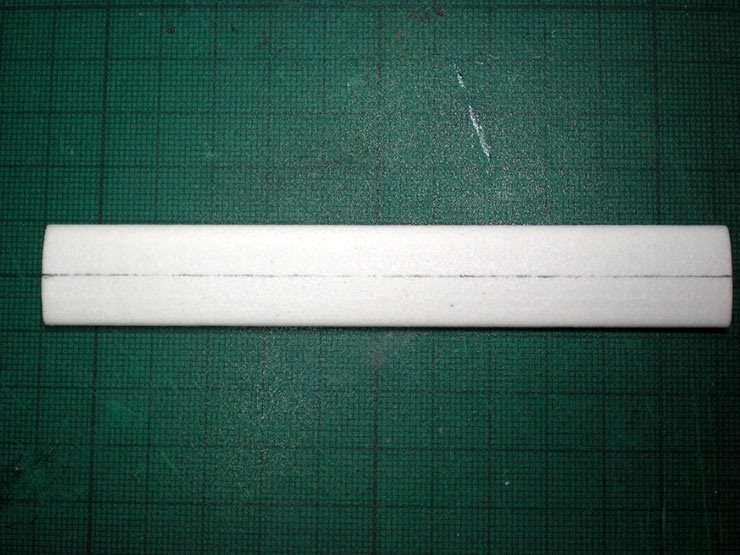

Now it's roof time, 3D-printed by Etched Pixels.

The first step is adding roof vents:

I've seen the way it can be done with a brass kit, but wanted

to simplify it. I marked out a centre line at each end, 9mm

being the line required:

Then filled in the rest of the centre line:

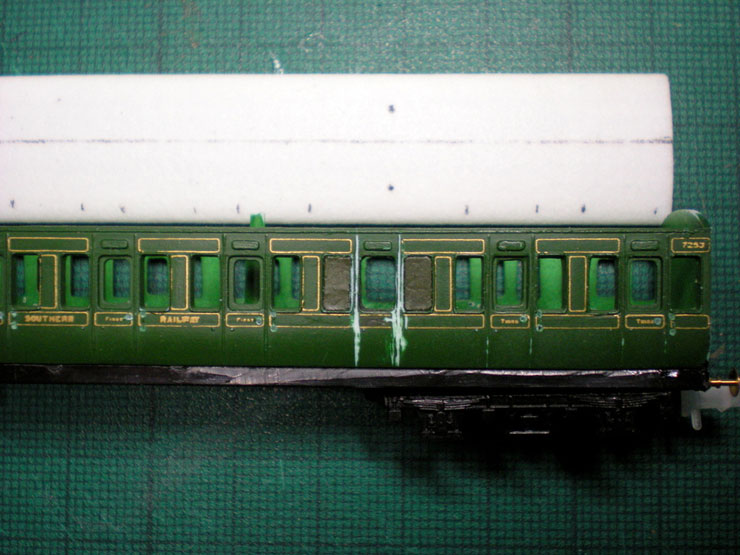

And then, keeping it very, very simple, lined up

the roof against the body and marked the centre of each

compartment's window seat (don't worry that it looks out of

alignment in the photo - that's because the windows you are looking

at are on the nearside, while the roof is sitting next to the

offside):

The next step will be to drill the holes.

28 May 2015

Time for another update. The work has been

proceeding apace, an hour or two most evenings and then leave

various bits to dry. Even so, it's taking a while, partially because

I'm still working out the correct order of works and partially

because I'm fine-tuning and correcting things as I go. It's really

starting to get there though.

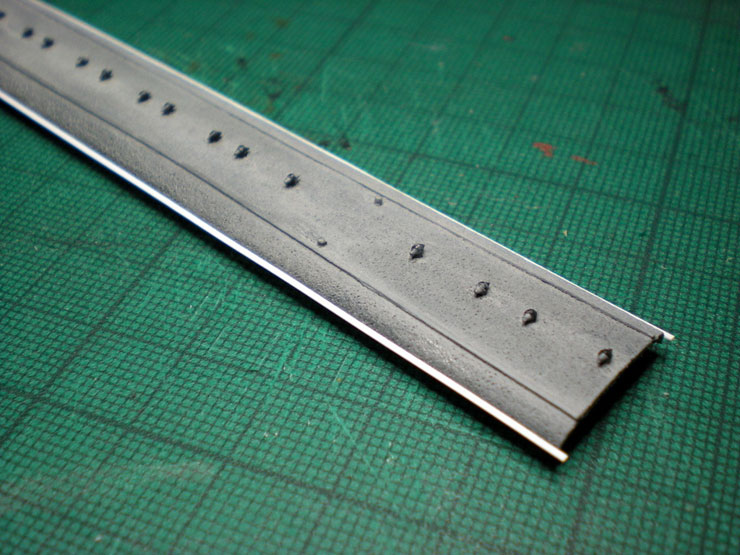

The roof has its rain strips and now also its

cantrails. These were quite tricky to attach. I used a thin line of

Bostik to get each one in place and then soaked in superglue from

underneath. It worked. They're about as solid as can be:

Fitting the grab handles and then door handles was

pretty easy, done over the space of two evenings. They were inserted

and then glued from inside where possible. Where not, a dab of glue

was added to the handle and it was guided carefully and quickly into

the slot:

Attaching grab handles to the roof was much

trickier, not helped by a blunt drill bit and a couple of breakages:

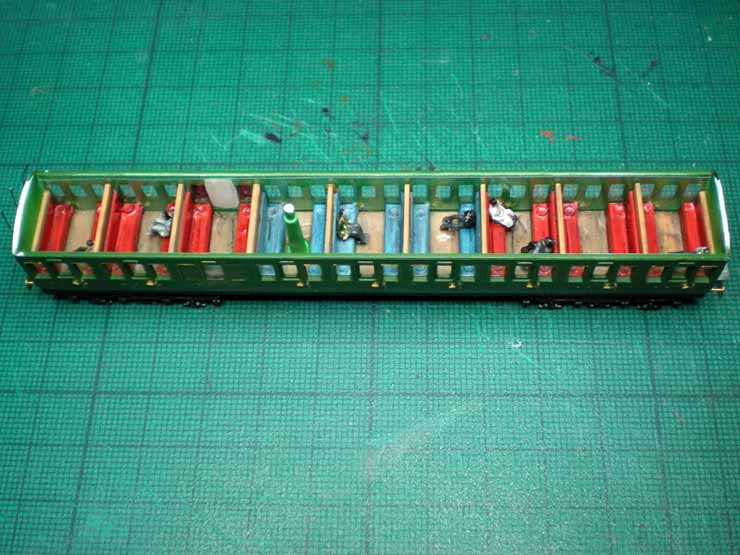

The green, red, and blue paintwork inside the

carriage was touched-up where the door handles had scraped through

it. It wasn't possible to fold over the handle shafts, so they were

painted instead. A test with the roof on seems to hide up any minor

'problems' like this:

Finally, for now, the microstrip used for the

cantrails seemed too thick when compared to line drawings. I'd use

the thinner version next time - the same thickness as for rain

strips. This time I filed them gently and also chamfered the

corners. They seem to work okay like this. The roof has been fully

undercoated and now has its first wash of Railmatch roof dirt. There

will be several more washes to come but I already like the toned

effect. This is a roof that started off white and darkened gradually

over years of service, so the washes should reflect that:

29 May 2015

I was going to scrape off the old carriage

numbering tonight but I was distracted by the realisation that the

planned-for set and side numbers were too late for 1930. Two hours

of research and head-scratching later and I've come up with 1910

four-car bogie sets and numbers that could well have been divided

into two-car units (or more probably three, but were certainly still

in use) until the early 1930s. That's probably the closest I can

hope to get with coach bodies which don't entirely match any diagram

anyway, so I'm happy with it.

20 June 2015

It's been a while coming, but I'm more than happy

to announce that construction work has been completed. Hurrah!

Here's how it happened. The roof was glued into

place (spot the new carriage numbering, although these decals are

not the sharpest I've ever seen):

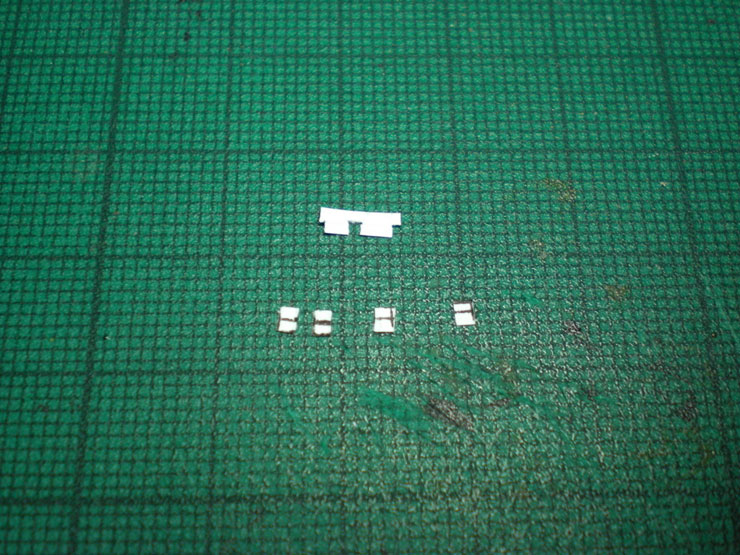

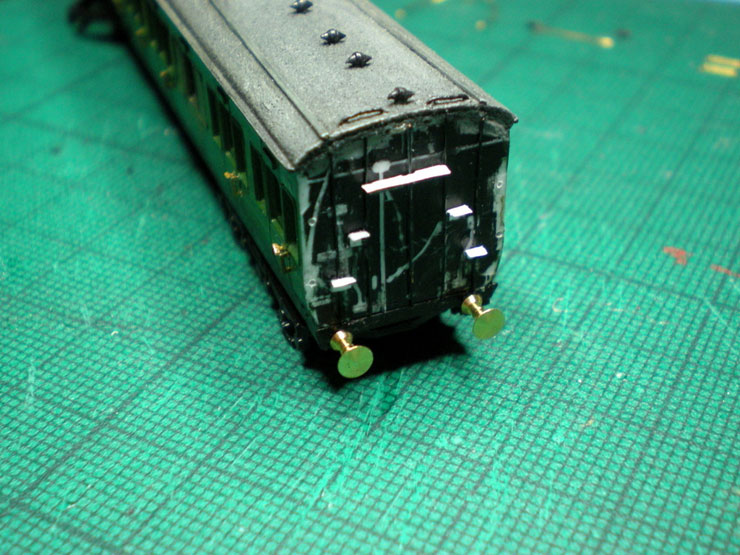

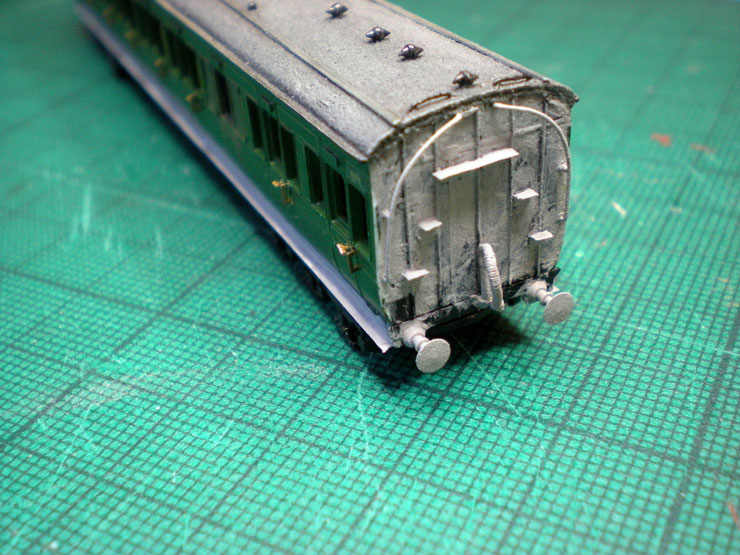

Next began the very tricky process of gluing the

vertical strips on each carriage end:

In fact it was so slow and fiddly that I worked out

a cheat for the other end - glue the strips onto paper and glue that

onto the end of the carriage. The bonus is that it will help to hide

any moulding details still present. Using a sharp knife, remove the

outer edge of paper so that the paper ends underneath the verticals.

There's less likelihood of it showing up that way:

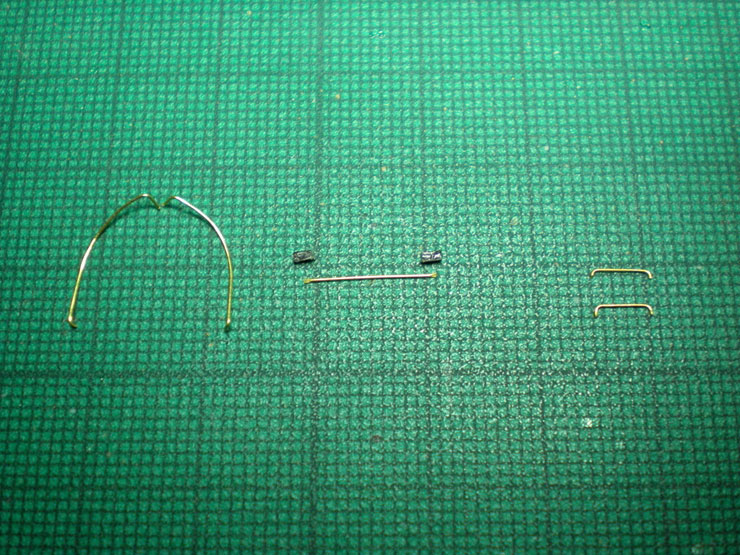

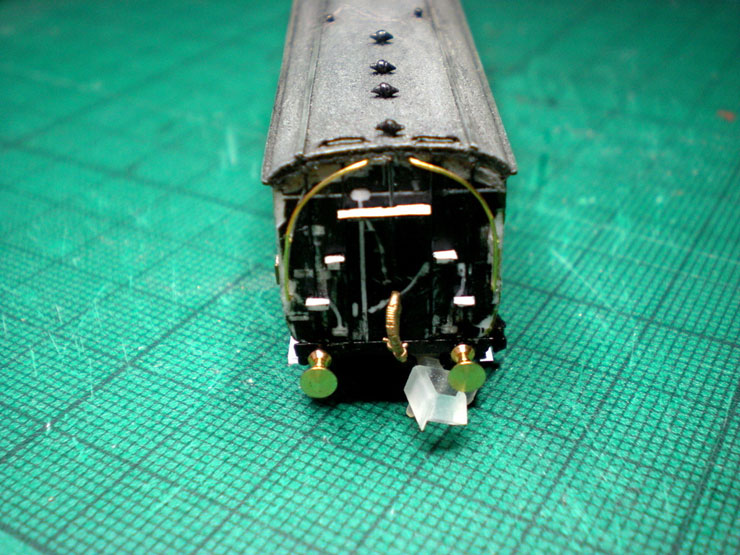

Now prepare the end detailing for the far end (the

non-steps end):

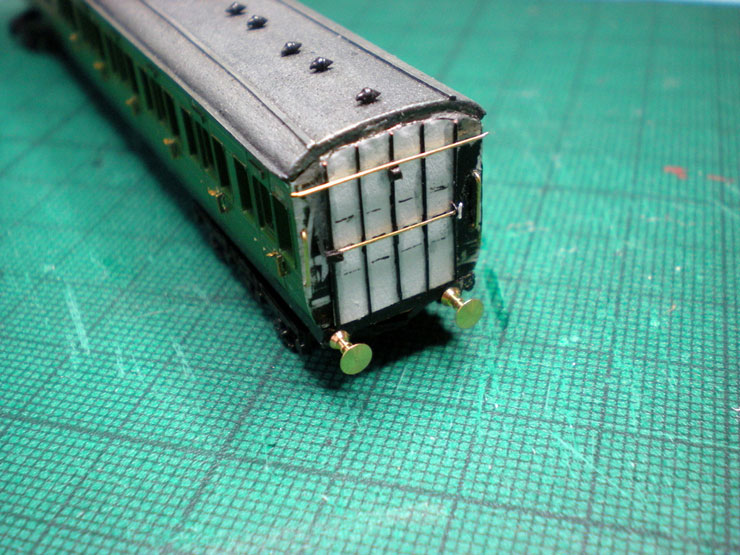

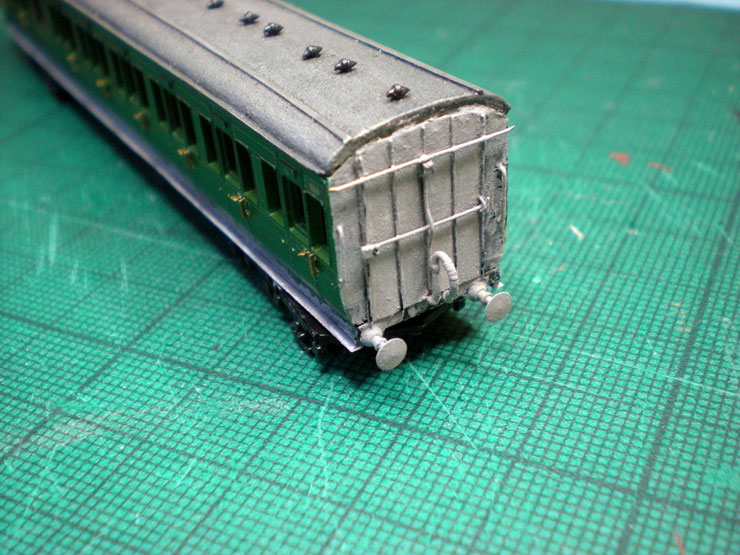

Vertical strips and cheat in place, horizontal rods

ready to go on:

Top rod in place, plus black box thing underneath

it (cut from a piece of removed

moulded battery box):

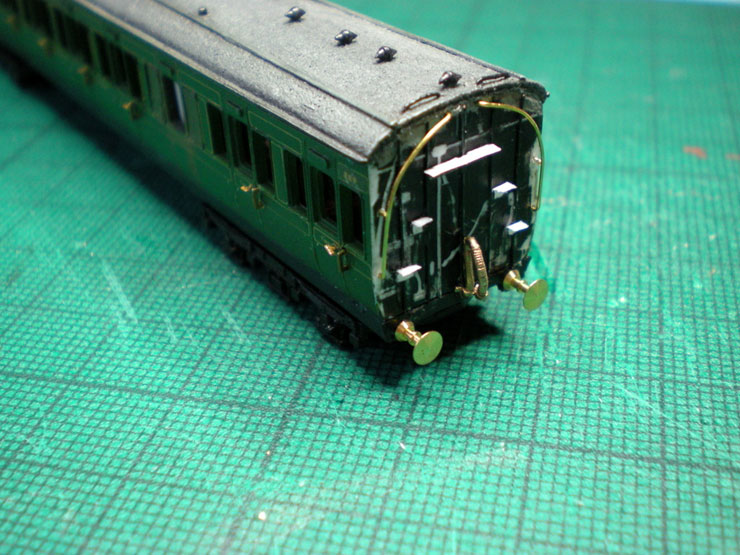

The second horizontal bar and black boxes, plus

vertical hand rails for the same

end and curved handrails for the

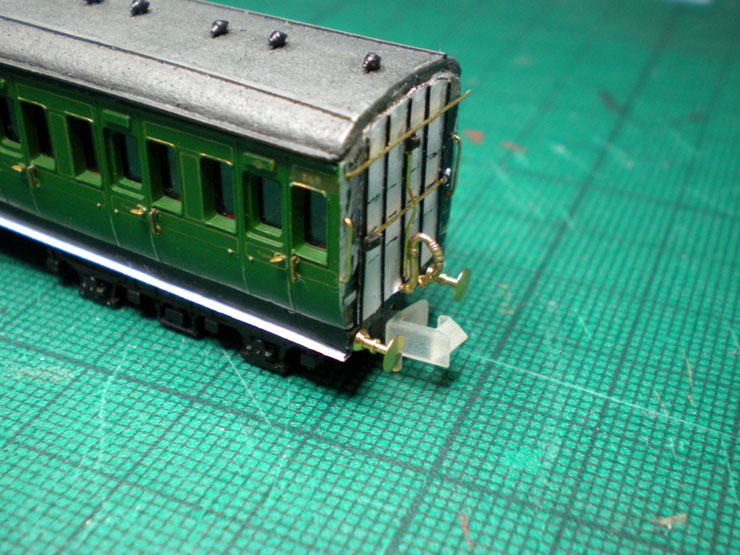

'steps' end of the carriage:

The steps themselves, using paper (I bet you didn't

see that coming). Simply fold

into an L-shape and soak gently in

superglue to harden:

Steps in place:

Curved hand rails added around the steps:

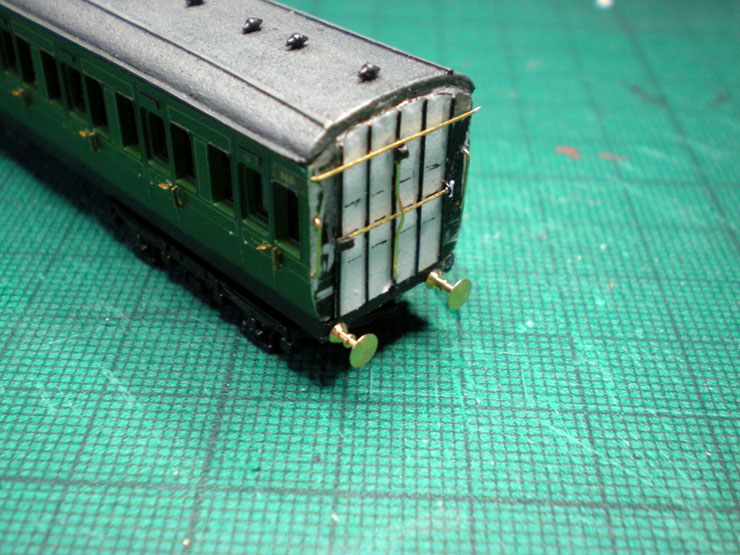

At the other end, the second horizontal rod in

place and also the vertical hand

rails:

N Brass vacuum pipe added, with the lower stock

bent into an L-shape and

inserted into pre-drilled hole on buffer

beam:

Vertical rod place on other end, although getting

the noticeable kink into this was

the work of over an hour:

Running boards added, using paper again, soaked

gently in superglue from

underneath until hardened:

Last vacuum pipe in place:

Full detailing on the 'steps' end:

Full detailing at the other end:

That's construction done. The next step is undercoating the new bits

and pieces prior to painting most of them black. Do you think it'll

pass muster?

21 June 2015

Reflections: the curved hand rails were

surprisingly easy to do, perhaps because there was more to hold

onto. The bottom 6mm was straight, so only the top part needed to be

rolled on a superglue cap and then folded at the tip to lock into

the pre-drilled hole under the roof. The 'U' bend was a nightmare

though! I would have used card for the running boards but there

really wasn't the clearance for the bogie, so paper it had to be. It

seems to be strong enough with 'responsible' handling.

I've done an undercoat tonight, which seems to bind

together all the various additions into one carriage. I'll take a

snap tomorrow.

22 June 2015

Here are the undercoating shots. It makes them look

a little like Farish or Dapol pre-production models (I wish). The

paint looks a little grainer in photo form than it does in real

life. One or two things I've noticed from this job is that the 3D

roof could have been a millimetre longer at each end to provide an

overhang. The torpedo vents could also have come with slightly

longer 'stalks' so that they could be properly raised above roof

level. Some of these look a little squat, and getting them to sit

just right was very fiddly.

After taking these shots, the first coat of black

went on. It takes a while to apply, what with all this detailing

getting in the way of the brush, but a second coat tomorrow may just

do the job.

23 June 2015

I think the blackness of the end panels will

largely disguise the lack of roof overhang for this coach (and for

the other roof I have), but when Mr Etched Pixels is more available

I'd like to ask him to produce the next batch slightly longer. There

was some filing involved to take off a bit of 'fluffiness' at the

ends, so this didn't help the length either.

24 June 2015

Not quite a 'trundling around the layout' shot just

yet, but apart from a bit of minor touching-up on the edges, the

main painting is done. So here's the just-about-finished article

without wheels, on the embankment:

The only thing that lets it down is the fact that I

couldn't match my olive paint touch-ups with the original Farish

green. Next time, no loos, and the results should be even better.

1 July 2015

Do you realise that it took a year, almost to the

day, to get this project from first post to last 'before and after'

shots? A good deal of that time was spent sourcing parts and getting

the roofs printed, but the work itself took from February to the end

of June. In my defence, a lot of it was experimental work, with lots

of testing and pondering and rewriting of the order of works, and

then a little light weathering to take the intensity out of the

black ends and running boards. I'm firmly convinced that the first

'production' upgrade will take much less time. In the meantime, here

are the before and after shots.

For anyone who plans to have a go themselves

(please do!), the complete and final order of works is at the start

of this thread.

|