|

|

26 June 2014

It's time to do some upgrade work on the Poole-era

Graham Farish suburban carriages to make them more LSWR-like (albeit

in SR livery and lettering). Fortunately there are quite a few

modelling aids for doing this sort of work, although it seems

strange that no one seems to have tried it before. At least, there

seems to be nothing online to say so.

There are a lot of problems with accuracy in the

Poole-era coaches (especially given the fact that they are closer

to LMS suburban carriages in their details than they are to any

LSWR carriages), but they'll do until someone produces a decent

range of bogie carriage LSWR kits.

The surgery won't involve anything drastic

like sawing a carriage in half and trimming its length (yet), but it

will involve creating new ends, probably fitting a roof, and adding

a lot of detail, but without damaging the lining which really can't

be replicated with a paintbrush, so here we go...

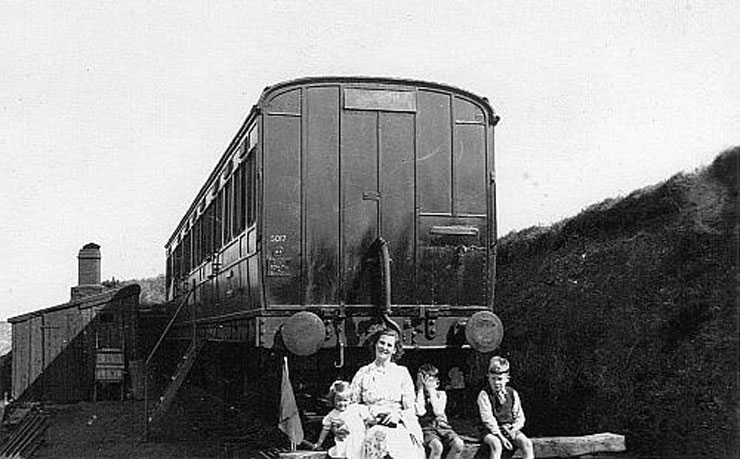

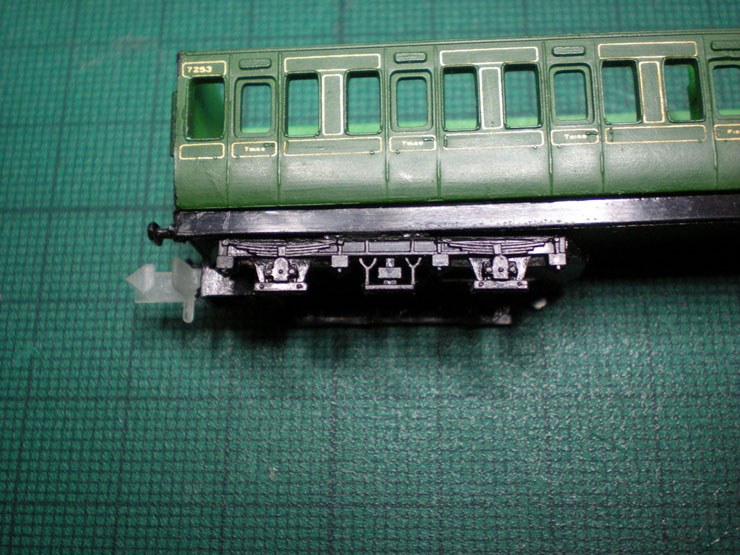

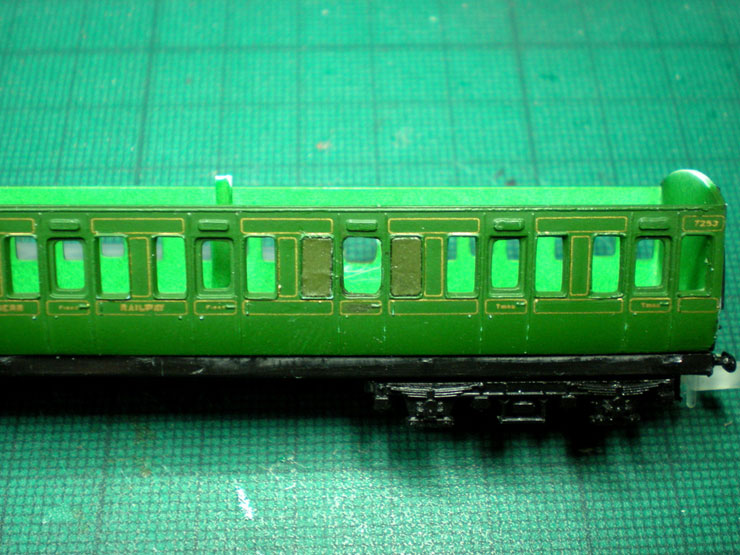

To start with, we have a Farish suburban composite

coach, side view:

...and end view:

...and a Farish suburban brake third, side view:

...and end view:

So these are the victims... I mean volunteers. At a little over 57ft

they'll do for matching up fairly closely to LSWR 56ft units of

1904-1910.

26 June 2014

Here's what I propose changing, preferably without

having to do any repainting so that the lining can be preserved:

- Fix the roof and carriage ends to create a

proper LSWR roof profile

- Add Ultima roof vents to centre line of roof

(14 for coach, 9 for brake)

- Add carriage end detailing including grab

handles on roof and grab rails over steps

- Add white backing to lavatory window on

coach and brake

- Add Ultima door handles

- Add BH Enterprises vacuum pipes to each

carriage end

- Add Ultima round buffers to each carriage

- Add Ultima guard's lookout ducket on each

side, either to replace the old one or midway along

- Add closer coupling between cars of the same

unit by shortening one coupling per unit

- Remove some dynamos/battery boxes from

underneath the carriage

- Renumber each unit

So what's needed to do all of that?

- Fix the roof using plasticard? What thickness?

Wire for rainstrips?

- Roof vents = Ultima LNWR/BR Ridged Dome Vent

(Pack of 25) UM256?

- Carriage end panel detailing:

- Carriage ends = plasticard shaped to permit

the LSWR roof profile?

- Thin wire glued vertically to create that

panelled appearance so typical of pre-Grouping carriages?

- Thicker wire for pipes, grab rails on roof,

and curved handrails?

- Plasticard for steps?

- White backing to lavatory window on composite

and brake = paper or white paint

- Door handles = Ultima LSWR Grab Rails and

Door Handles (Pack of 250) UM336

- Vacuum pipes = BH Enterprises (Pack of 4)

BHE411 (ordered but awaiting confirmation)

- Round buffers = Ultima Oval Coach Buffers (Pack

of 4) UM103

- Guard's lookout ducket = Ultima LSWR Etched

Duckets (4 Pack) LSW97?

- Add closer coupling = cut down one coupling to

reduce length and glue back into position?

- Remove dynamos/battery boxes = drill out and

file, or remove entire section and replace with wire?

- Renumber each unit = SR carriage side numbers?

Some of the questions have been answered during

several hours of research and scribbling. And after some sourcing of

parts a final list of requirements was drawn up:

- Use either 0.2mm wire or printer paper for

rain strips

- Use Microstrip .010x.025 for cantrails along

the edge of the roof (rain gutters)

- Roof vents = Ultima LMS/LNER/SR Torpedo Vent

Plastic (Pack of 32) UM252

- Carriage end panel detailing:

- Carriage ends = strip detail off existing

ends and shape to LSWR roof profile (minor filling required)

- Add Black Brass Wire 0.2mm (50m) from

Luna Jewellery Cat 3011 (via eBay) to create panelled appearance

- Add 0.33mm handrail wire for pipes, grab

rails on roof, and curved handrails

- Use either card or thick paper for steps

- Paint white backing to lavatory window on

the transparent window strips

- Door handles = Ultima LSWR Grab Rails and

Door Handles (Pack of 250) UM336

- Vacuum pipes = BH Enterprises (Pack of 4)

BHE411

- Round buffers = Ultima LMS-Style Round

Coach Buffers (Pack of 4) UM103 (use UM103 oval for Emigrant stock)

- Guard's lookout ducket (larger than Farish

version) = Ultima LSWR Etched Duckets (4 Pack) LSW97

- Closer coupling = Shapeways clear couplers

(small shank when using original coach buffers)

- Remove dynamos/battery boxes = drill out

and file, and replace with 4.8mm x 4.8mm balsa boxes

- Renumbering each carriage = Fox Transfers

Bulleid sheet FRH 2404

- Replace pizza-cutter wheels = BR Lines 7.0mm

Wheels for Coaches - Solid Blackened (Pack of 4) GF2109-C

- Add set numbers = Fox Transfers SR Coaching

Stock Set Numbers (small) FRH2404/35

- Add seated passengers = Seated N Gauge

Passengers 1:150 Generic, from Everest, Cat P150S, via eBay

27 June 2014

I'm happy to make believe that these carriages are

56 footers so that I don't have to chop off bits (which would mean

buying the appropriate cutting instruments).

These two coaches will form a permanent two-car

set. The set numbers can be bought from Fox, but I haven't located

individual SR coach running numbers yet.

To my mind, the roof profile is one of the most

important things to change, along with adding the torpedo vents.

After all, it's the roof that will be seen most often when the

carriages are on the layout.

28 June 2014

There seem to be two viable options for the roof -

contact Etched Pixels or use card because it will be much easier to

shape than plasticard.

The existing shape is too flat at the corners

though. That weird LSWR roof shape demands a much squarer corner, so

card will probably be the way to go. Once the vertical strips,

pipes, steps, grab rails, rooftop handles, and vacuum pipes are

added it should look pretty good.

The lower bar needs to be snipped off each bogie. I

have no plans to swap out the actual bogies, but this is another

minor change that will help to make them look less like generic

Poole-era plastic coaches and more like the representative (in the

broadest sense) coaches that I'm aiming for. They'll never be

perfect (the doors and windows are marginally inaccurate for a

start), but they will look right to the average viewer, and they'll

look very much upgraded and amended as much as possible, which is

what's important.

The battery boxes on some coaches in each set need

to be removed, too. I'm wondering if drilling and filing is the best

way to do this. I think the roofs will be the most important, and

most noticeable change, but the rest will certainly help.

As for the seating, the Southern Railway seems to

use dark red for second class seating and blue/grey in first class.

10 December 2014

Believe it or not, it has taken since July to pull

all of the pieces together for this project, and now I'm too busy

with work and preparing an imminent publication on the

History

Files to be able to get started until after Christmas. Oh well,

at least I can go over all the parts. Many of these were the result

of recommendations from the NGF, so thanks are due here to everyone

who helped.

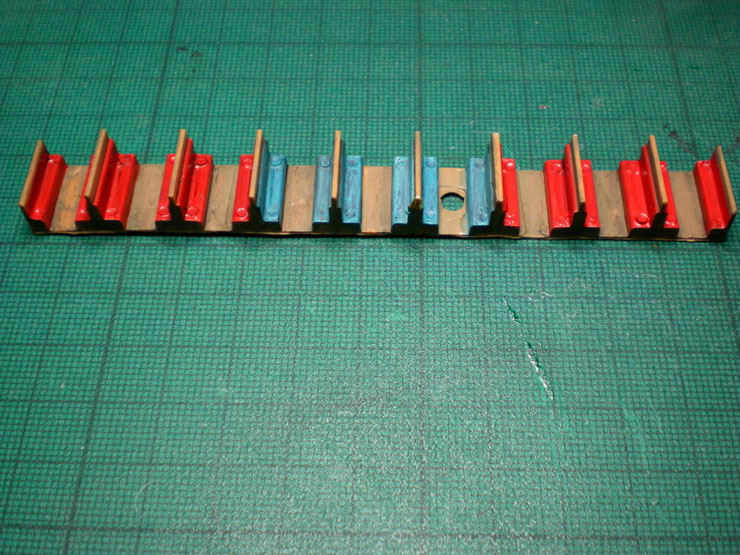

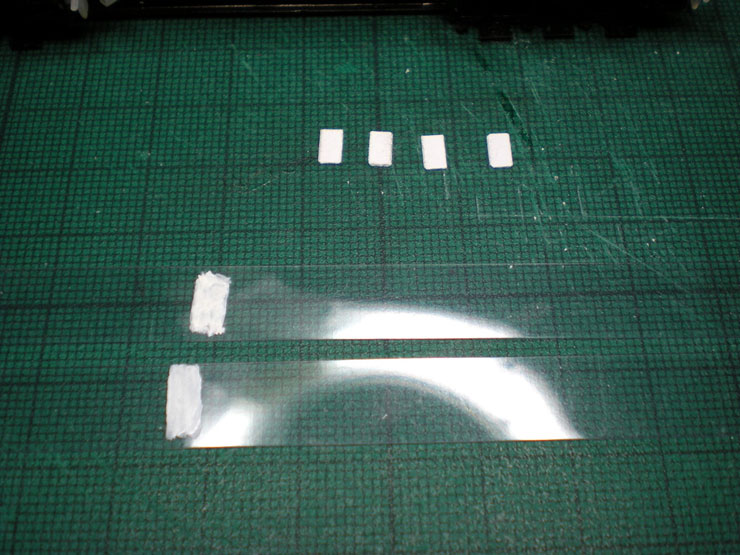

From the back, left to right are the following:

- SR Coaching Stock Set Numbers (small),

Fox Transfers, FRH2404/35

- Coach Numbering Metallic Gold, Fox

Transfers, FRH2013

- Black Brass Wire 0.2mm (50m) (for end

vertical strips), Luna Jewellery (via eBay), Code 3011

- LSWR Grab Rails and Door Handles

(Pack of 250), Etched Pixels, UM336

- LSWR Etched Duckets (Pack of 4, two

needed for the brake in this project), Etched Pixels, LSW97

- LMS/LNER/SR Torpedo Vent Plastic

(Pack of 32), Etched Pixels, UM252

- Replacement 7.0mm Wheels for Coaches

- Solid Blackened (Pack of 4), Etched Pixels, UM180

From centre back to front:

- Plastic glazing strips from the Farish

coach

- Emptied Farish shell, with one of the

battery boxes to the right

- Farish seats, ready to paint

- LSWR carriage roof, printed in 3D by

Etched Pixels, LSW96

- Brass handrail wire 0.33mm for

rainstrips and hand rails

Front, left to right:

- Semi-transparent Rapido couplers to

experiment with closer coupling, 3DR<.li>

- LMS-Style Round Coach Buffers (Pack of

4) , Etched Pixels, LSW97

- White metal vacuum pipes, BH Enterprises,

BHE411

Plus I need to source some plasticard or good quality

card for the end panels, end panel steps, and also a strip along the

top of the chassis to provide the missing running board on each side.

We're just about ready to go... possibly.

10 December 2014

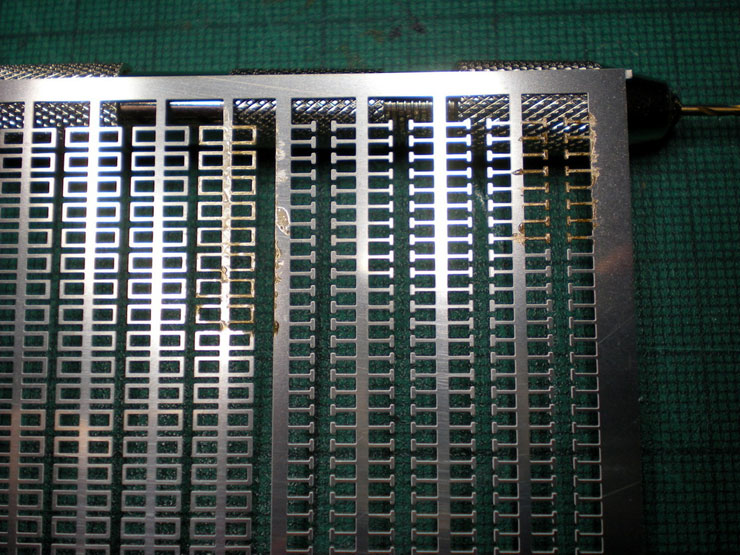

The 'Luna Jewellery' pink/white/blue reel at the

back is actually black wire. I'm going to use that to provide the

vertical 'stripes' on the carriage ends:

27 March 2015

And we're off... finally.

Order of Works (See Southern Coaches Plate 121 &

LSWR Carriages of the 20th Century Figure 6.13 & Plates 6.12a-e):

Paint internal coach seats dark red for third class

and dulled blue/grey for third

Repaint brown wooden areas in brown and leave toilet section black

Add closer coupling between cars of the same unit by replacing with

shortest 3DR Rapidos

Bodywork (underframe)

- Remove dynamos/battery boxes from underneath every one carriage in

two, whether brake or non-brake

- Remove moulded dynamo boxes from other coach and tidy frame

- Clip off the lower bar on each bogie (keep for later)

Bodywork (end pieces)

- File or scrape off moulded detail on each end of carriage.

- Cut off old buffers

- Trim off about two millimetres from the roof's support (but not

the roof!), where it overlaps the carriage ends

- Gently file the old carriage end pieces to match the new roof

profile

- Drill through old buffer stubs so that Ultima buffers can be

fitted

- Drill an 0.8mm hole at the very centre of each buffer beam so that

it can house the vacuum pipe

- On the end furthest from where the roof grab handles will be,

drill four holes for two vertical hand

rails, about 1mm from each

edge:

- Two either side, just above centreline of the carriage windows

- Two either side, central to the panelling underneath the carriage

windows

- Attach Ultima buffers, rounded for some carriage types, oval for

others, filed a little on top and with a filed

slot into the

carriage base so that they sit level and straight before being

superglued in place (with a Bostik

mix for flexibility)

Bodywork (toilet and handles)

- Open up the window frame for the third door from the end for

toilet (the last third class door)

- File off toilet window door frame and also handle and grab handle

- Remove vertical gilt edging so that it can be joined up

horizontally along the entire section

- Add white backing to toilet window on either side carriage

- Use an old coach or wagon wheelset to make a positioning hole

immediately above and below old grab handles

- Drill each grab handle hole with an 0.5 bit

- Use old wheelset to place another positioning hole centred on each

of the old door handles

- Place seating strip and window strips back in place and re-drill

door handle holes

- Remove seats and strips and greatly enlarge those holes only (not

the holes in the bodywork) so that the

door handles will easily fit

into them

- Block up windows on either side of toilet window - use card cut to

shape, slightly rounded at the corners,

and painted before fitting.

- Strengthen blocked-up windows from behind by adding the

clipped-off bogie tie bars as vertical supports

Roof (and fitting parts together)

- Ensure roof fits snugly into position

- Add Ultima roof vents to centre line of roof, positioned laterally

over each compartment - (16 for coach, 9 for

brake), but not over

toilet 'compartment', using 1.0 drill bit, opening up hole a little

- Add smaller vent with 0.8 drill bit and use points motor throw bar

steel rod cut to 2-3mm lengths and rounded

at the end with a file)

over toilets, one one on either side of roof for each toilet

- Add Microstrip .010 x .020 as rain strips to roof, starting from

centre and working towards the ends

- Paint seated passengers

- Fit and lightly glue window strips into place

- Fit seating unit in place, and check that holes for door handles,

etc, can still be used (re-drill)

- Paint all door handle holes in Railmatch Light Olive Green mixed

with a touch of a golden yellow colour

- Paint filed-off door frame for toilet (Maunsell Green)

- Insert grab handles, and glue from the back where possible, or

insert a touch of glue into hole with a pin

- Insert door handles, and repeat glueing process

- Fix any damage to internal paintwork and seats caused by drilling

and sticking handles

- Touch up all green paint where needed

- Fill in any gaps in gold carriage lining using brass enamel paint

(correct errors with more Maunsell Green)

- Glue seated passengers into position

- Add new dynamo boxes under carriage body, behind tidied frame,

using squared Balsa (on one carriage in two)

- Add Microstrip .010 x .020 as cantrails to edges of roof

(guttering over each side of the carriage) - attach

with Bostik and then glue from underneath with superglue before

chamfering corners

- Add end grab handles on roof

- Undercoat roof to hide all pen guide lines (white or light grey)

- Wash roof in successive thinned layers of Railmatch Roof Dirt (or

dark grey) until satisfied with colour

- Scrape off old carriage numbers

- Renumber carriages

- Refit underframe (easier and safer to do before roof is fitted)

- Fit new roof, glue in place

- Fill gaps between roof and carriage ends

Fittings (end pieces)

- Cut out a templated end piece of paper and add five end vertical

strips to both of them

- When dry, secure in place on carriage ends, overlying old, filed,

detailing, & trimmed outside outermost strips

- Add pipework to one carriage end, furthest from the roof grab

handles:

- One 0.33mm brass rod cut to 17.5mm and with ends crimped flat,

then bend the ends to 90 degrees,

backwards, so that they can make

contact with the carriage ends (or close to it)

- Secure this in place, horizontally, level with the strip above the

window vents, just below cantrail level

- Cut a small squared piece from the discarded Farish moulded

battery boxes, roughly 1mm wide by 1.5mm long,

or close to it and

secure this centrally, immediately below the top horizontal bar and

touching it

- Add vertical hand rails to the same end, in the previously-drilled

holes, 1mm from each side edge, using brass

rod that is 4.5mm long

(excluding the L-shaped bent-over ends that fit into the drilled

holes)

- One 0.33mm brass rod cut to 12.0mm and with ends crimped flat

- Secure this in place, horizontally, centred against the vertical

hand rails on each side of it

- Cut two small rectangular pieces from the moulded battery boxes,

approximately 1mm high by 2mm long,

and secure these to the crimped

ends of the second horizontal bar (or one piece at one end and a

piece of

curved brass wire and a sliver of paper to mimic equipment

on some diagrams of coach

- Add vertical pipe centrally, cutting 0.33mm brass rod to 111mm and

crimping one end to climb over the central

horizontal rod so that it

touches the small squared box below the upper horizontal rod, and

continues down

from there to the buffer bar beam. Secure

- Add N Brass vacuum pipe over the vertical panelling strip after

bending the lowest section of the pipe into a

reversed L-shape -

insert this section into the previously-drilled central hole in the

buffer beam

- Add steps and rails to other carriage end, nearest the roof grab

handles:

- Add four new foot steps to the other carriage end (paper cut 2mm

high, folded in half into an L-shape, and

1mm wide, superglued so

that they harden), secure one side of L-shape to carriage end

- Add one new foot step above the other four (folded paper, 2mm

high, 6.5mm wide)

- Add stub of brass rod to previously-drilled holes, level with the

strip above the windows, protruding by about 1mm - these will

support the curved hand rails

- Create curved hand rails with two pieces of 0.33mm brass rod -

these should be straight for 6mm so that they

will rest on the stubs

at the 5.5mm mark and bent at the base so that they will slot into

the lower of the

handrail holes that are 1mm in from the side

- Now curve the rest of the hand rail brass rod gently to produce an

arc, bending at the top of the arc so that it

enters the drilled

hole just under the roof , about 1.5mm away from central vertical

panelling line, and also

secure them by gluing to stubs

- Add N Brass vacuum pipe over the vertical panelling strip after

bending the lowest section of the pipe into a

reversed L-shape -

insert this section into the previously-drilled central hole in the

buffer beam

- If necessary - add Ultima guard's lookout ducket on each side of

brake, to replace the old one

- Add running boards to each carriage side using paper, 1mm wide x

119.5mm long, glued to the underside of

the chassis edge line

- Undercoat any bared surfaces, including all end carriage detailing

- Touch up all green paint where necessary

- Touch up brass where necessary

- Touch up black areas where necessary

- Lightly varnish carriage ends, then add a touch of gloss varnish

so that carriage set numbers can be added

- Add carriage set numbers, centrally positioned on the upper

carriage ends, below the main step at that end,

but normally only on

brake ends of a set (LSWR Miscellany p35 - 1922, LSWR Carriages of

the 20th Century

p35 - 1937)

Varnish entire carriage where necessary

Lightly weather in layers so that dirt builds up in cracks and

doorways and on the carriage ends

Add new wheels to bogies

Done!

Now, this may be the final order of works list, but

it took all of the steps below to finalise it. So what you see below

here are all the steps listed above, but not necessarily in the

correct order.

10 April 2015

Progress has been slow to start with, mostly due to

some fine weather and lots of outside jobs. But there has been a

little progress.

Two coats of red acrylic, one coat of oil-based

Prussian Blue (S&DJR Blue, all I have) and a very dodgy oil/acrylic

mix to lighten it. Note to self, must mix oils with oils. The brown

has been repainted and the whole thing was given a wash of black to

tone it down:

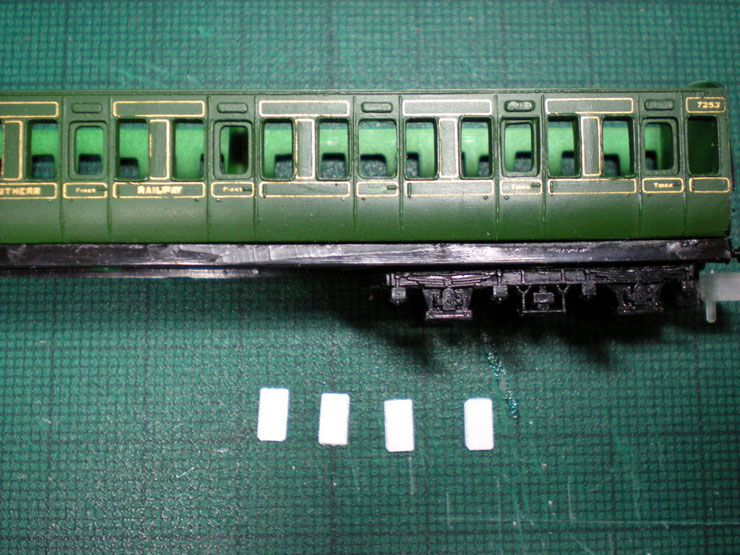

Cut out the fake battery boxes from the frames.

There won't be any battery boxes on this carriage, but for next

time, I'll use square balsa wood for some standalone boxes to fit

behind the frame.

And then onto the bogies. Before:

...and after:

The trick is to hold the rather flexible bogie

frame near the middle. Then gently, and lightly, saw through with a

modelling knife. Each bar cuts through in only a few seconds and

they come off very easily.

That's it for now.

11 April 2015

Why put in all this work? Mostly because there's

nothing compatible available.

The new Dapol coaches (2015 release) are Maunsell

low window stock of 1926 onwards. But for anyone modelling the

pre-war period they're still pretty new and are used on premier

services. Most other services would still have used pre-Grouping and

early Grouping stock, which is why it's important to be able to make

these old Farish suburbans look better. They remained in service

right up until the 1950s, so this work is valid for just about any

steam period.

20 April 2015

Time for an update.

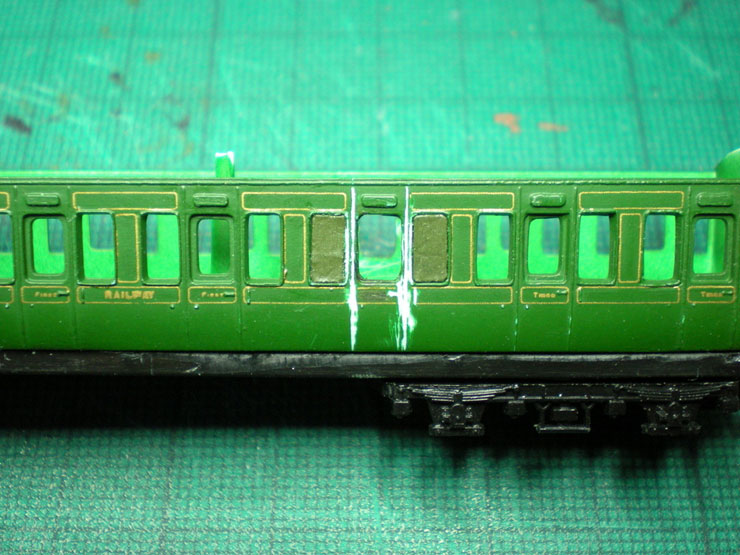

After painting the seats and then filing off the

droplight framing in the third door from the end (see below), I

suddenly also realised that I'd have two side windows that would

show seats in a toilet! Some hurried blocking-in was arranged. I

tried plasticard, but what I have here is too thick and wouldn't

file to a straight edge, so I went back to my personal favourite -

card:

I also painted in the white toilet window frosting:

Then I undercoated the blocking-in and over-painted

with Railmatch 2630 SR Light Olive Green Acrylic. It's very close to

the green used on the coaches, perhaps just needing a touch of

lightening for the final coat later. Here they are glued in place.

The clipped-off bogie tie bars are perfect for gluing in behind the

card as strengthening bars:

The next step (which really should have been the

step before the last step) was to file off the door frame and

handles. I soon realised that a file was too generalised and instead

used a sharp craft knife to peel them off:

That's all for that section for now. Painting all

the cracks and filing and gaps, etc, will come at the end. The next

step is to add door handles and grab handles, so it makes sense to

paint them in brass first. Even if some of the paint comes off

during handling, it'll be easier to touch it up when they're in

place than it would be to paint them from scratch:

Next comes drilling the holes in the carriage and

inserting the first handles...

|

|