|

16 July 2017

Being a sucker for punishment, when I found out

that LSWR block sets of 6-wheel carriages were still around in 1930,

and that Etched Pixels have produced them as part of the Ultima

range, I decided that I needed some of them.

By 1930, many of the first class carriages had been

collected together into three 'race sets', providing better

accommodation in special services from various towns in the south of

England to a day at the races. There were quite a few famous race

courses and meetings in the Southern Railway area (there still are,

but most people these days go by car).

Each race set was formed of ten 6-wheel carriages,

with a saloon at each end with normal couplings, then a first class

coach with normal couplings at the saloon end and close-coupled at

the inner end, followed by six more firsts, all close-coupled. The

close-coupling was little more than a bar connecting carriages and a

sort of 'bump' panel on each coach. Repeating that in N Gauge for

tighter-radius curves would be a bit of a challenge, but I've done

something similar with the double brake van (see page 6 of the

general Grouping Workbench pages).

A smidge of common sense sneaked in, and I

shortened the ten-car set to eight, but that's still quite a bit of

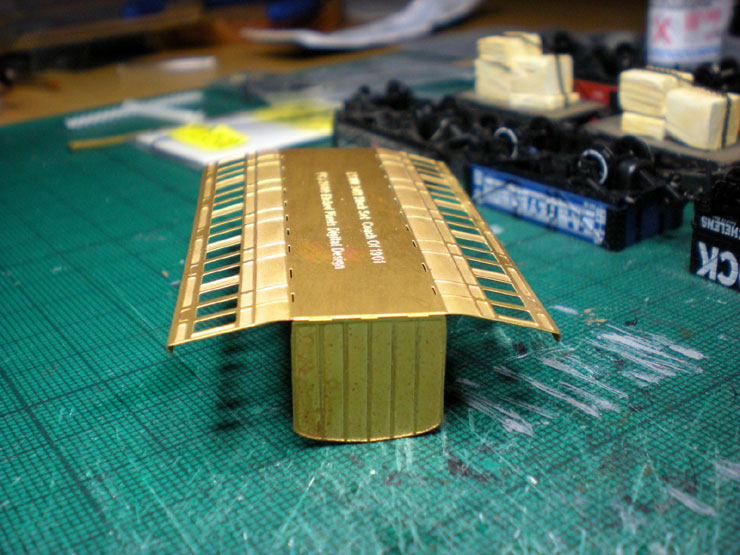

building. The Ultima 'kits' are supplied in etched brass, as in the

photo below. The roof is at the top, the main carriage body and

floor in the middle, and the standalone 'droplights' at either side.

These need to be separately painted and glued in behind the doors...

but there's also the 'tumblehome' to take into account here - the

gentle inwards curve of the carriage body at the bottom of the side

panels - and that complicates things quite a bit.

Anyway, on with the work on one of the central

close-coupled firsts as a test coach. This one took a couple of

months, on and off, as I had to work out how best to do several of

the more tricky stages of the work.

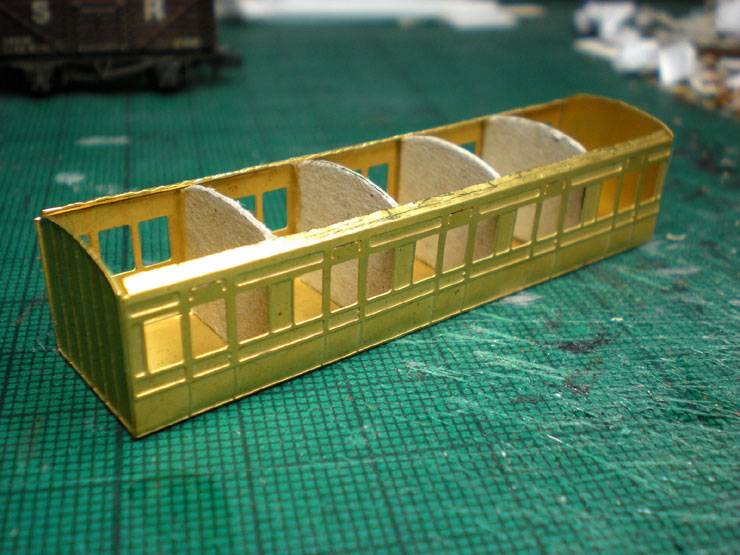

Remove the brass pieces from the etch and fold up the main body,

adding the

tumblehome curve to the lower side panels. That's harder than it

might seem, and

getting a consistent curve along the entire side panel means a bit

of adjusting.

There were no instructions regarding the interior so I made up my

own

compartment dividers from card and also used these to glue the body

in place. Yes,

gluing. I'm not risking a soldering iron on this!

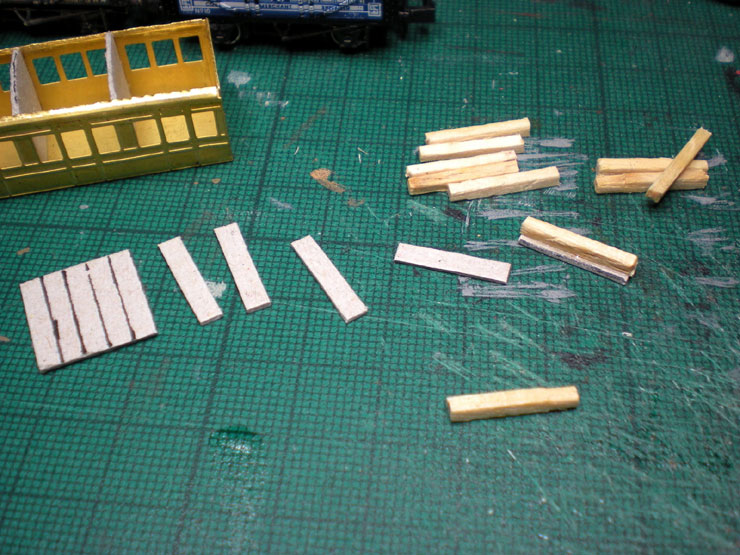

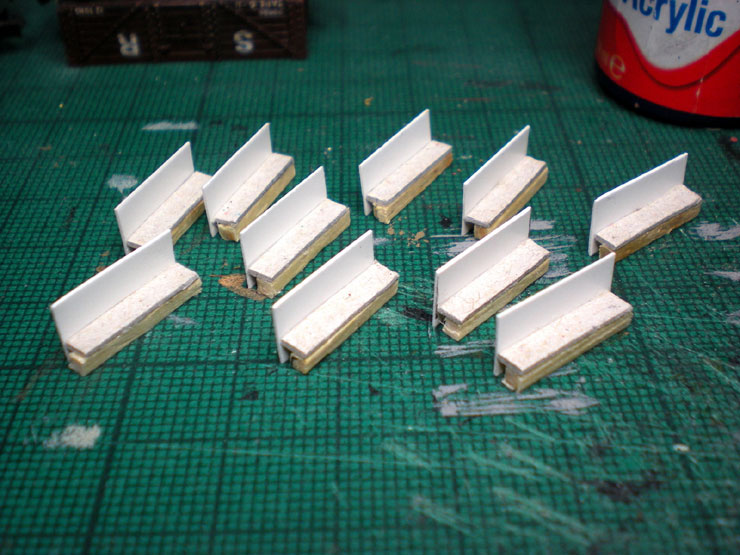

Next I needed bench seats for each compartment, so that meant

cutting card and

matchsticks.

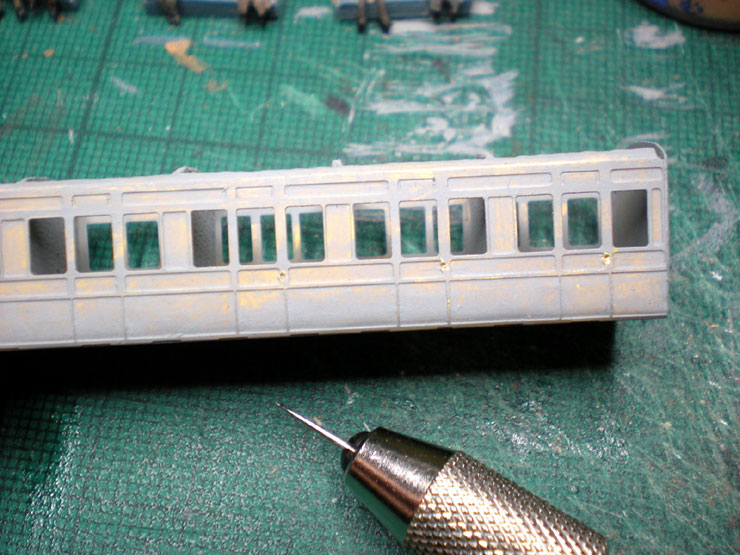

Something else was needed - door handles. I usually add grab handles

too, but

the Etched Pixel ones seemed too large for this kit, so only the

door handles would

be added. Drilling through the brass proved impossible with a hand

drill. It just

wouldn't go anywhere, and pushing against the assembled coach body

was

denting it quite badly - note to self, drill door handle holes

before assembling body

next time. In the end I put a darning needle in the hand drill and

used that. It went

through the brass very easily.

A piece of card to serve as the back rest completed my bench seats.

Now all the seats were painted in first class blue and some

crazily-coloured

passengers were added. Well, you lot can't go to the races in 1930

dressed like

that, so we'll have to get you kitted out in more appropriate

colours.

They were all undercoated in grey before receiving a batch of muted

colours -

greys, browns, and blacks mostly, with the odd dull green or blue.

The finished

result will be seen later.

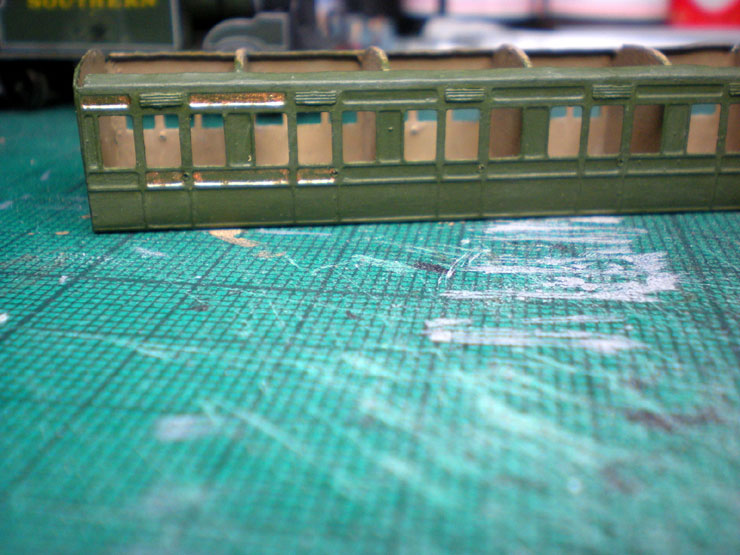

With the door handle holes drilled and top lights added (the grooved

panels above

the doors), it was time to start painting the body inside and out

(wood-brown and

Maunsell Green respectively). The brass roof was bent to shape and

drilled so that

the torpedo vents could be added.

I did toy with the idea of adding the gold lining by filling in the

panels and painting

the green over the insides of each panel until only a fine line was

left. In the end it

proved too unreliable a process and I don't have a good enough

paintbrush. The

next time I buy paintbrushes, I'll splash out on a quality set that

will actually last.

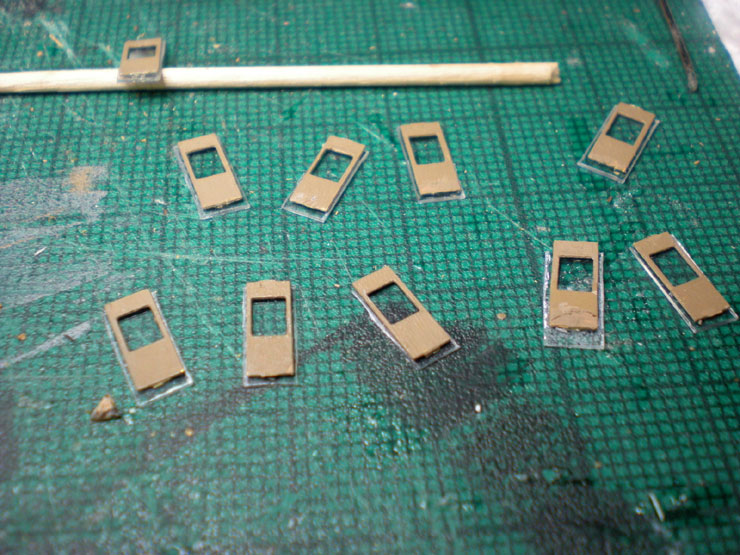

The droplights were painted up and I added clear perspex behind them

to mimic

glass. In the end this didn't work out as the perspex kept falling

off. I found a

thinner perspex to be added on after the droplights were fixed to

the carriage...

Thinner perspex in place over the side windows (this is a very

fiddly job!). Space

left for the droplights...

Now the droplights have been added, although they fit very badly and

needed a

good deal of extra superglue added top and bottom before I felt

reassured that

they weren't going to fall off at the slightest handling.

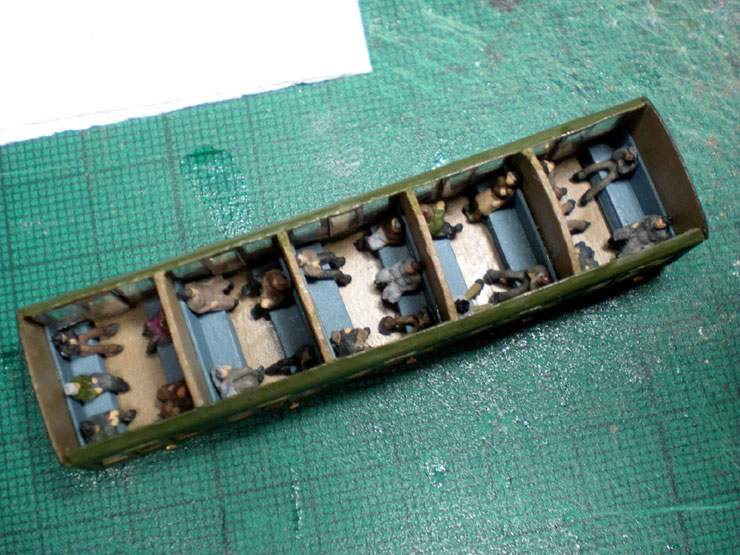

Now the passengers could be lowered in by crane, already attached to

their seats

(Southern and Southeastern take note - you'll be doing it like this

before long). The

benches were a little long at first, catching on the perspex, but a

bit of careful

trimming meant that they fitted in the end. You can see the final

colours used on

the clothing here.

Now the roof could go on. Since that was last seen, I've added rain

strips and

cantrails. The cantrail at the roof's long edge helps to disguise a

small gap between

roof and coach body. A bit of filler hides the slight gap at the

ends.

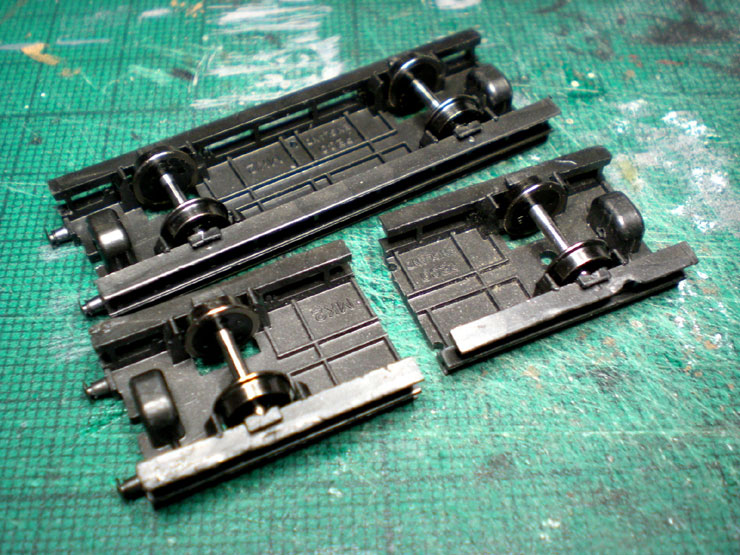

Now for the wheels. There were a couple of choices

for this, with the Stove R 6-wheel chassis being one. But that needs

a lot of alteration to make it a proper 6-wheel carriage chassis with

a running board and running step (see the

S&DJR Farish

Carriage Conversion thread to see how I did this previously).

Someone came up with the idea of using the chassis from a Peco brake

van, which already had the running boards in place, and this is what

I went with.

To get the correct wheel spacing that meant chopping two chassis

into four pieces

and using three of those pieces. It took a while to work out the

proper lengths but

the cutting part was easy enough. A little filing made sure that the

fit was about as

flush as could be hoped for.

You can see the gaps between the three chassis pieces here, although

it's the

running boards that really have to be matched up as this is what

will show when

the carriage is on the tracks.

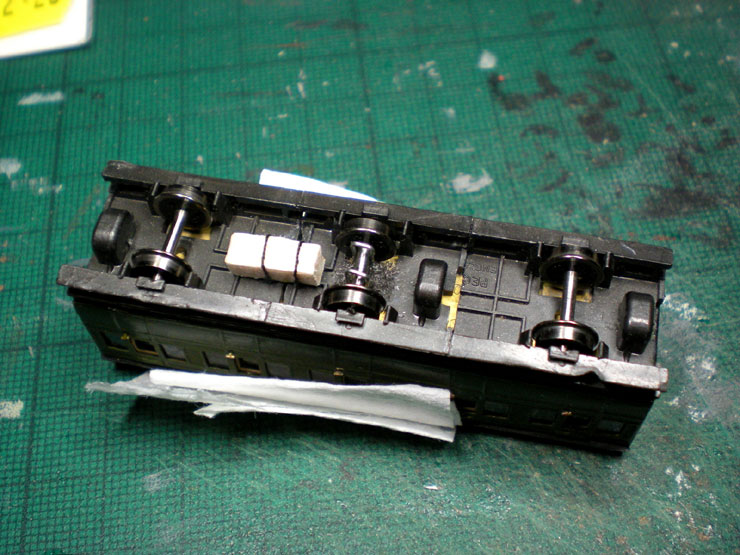

The middle set of wheels couldn't be fitted in the normal way. The

length of the

carriage meant that fixed wheels forced it to derail on some of the

tighter curves on

my layout. Instead I followed the principles set by the Stove R

chassis and created

a stand-alone, free-floating wheel holder - two staples bent to

shape and glued

into drilled holes in the chassis. That really does do the trick,

although it's best to

add a soft piece of foam underneath to help keep the wheels down,

and also to file

off the spiked wheel points that would normally hold the wheels in

place in the axle

box. This bit is important to get right or the filed wheel ends will

catch on the

chassis and cause all sorts of problems. File the wheel points flat

and you'll have

some wonderfully free running.

Also added here is the battery box so ensure electrical lighting to

the carriages. I'd

do the dynamo too (which generates the electrical charge as the

carriage wheels

turn) but it's a flimsy piece of equipment in N Gauge terms and I

haven't found a

satisfactory way of representing it.

One of the last steps is to add Fox Transfers' 'Southern Railway'

lettering above the

window line, and the class lettering on each door, plus the carriage

number - four

times no less, twice per side!

The brass door handles show up well here, and you can see the little

bits of filler

used to mask the gaps between the three chassis pieces. When filed

and painted

black you'll never even know those gaps were there in the first

place.

A slightly murky shot of the carriage on the layout, although it

doesn't have any

couplers as yet. A staple will serve as the connecting bar between

carriages, with a

spring on one end to force them to close couple, but still allowing

them to open up

on the tight curves.

The next stage will be to built an end-first and a saloon so that I

can get a normal

Rapido coupling on the set and actually connect it up to a loco. At

the moment it

can only be used in push-push services... and not on any hills!

|